5+ Sample Inventory Action Plan

FREE Inventory Action Plan s to Download

5+ Sample Inventory Action Plan

an Inventory Planning?

Benefits of Inventory Planning

Inventory Management Strategies

How To Develop an Inventory Action Plan

FAQs

How do you keep track of your inventory?

What is the purpose of a blind inventory count?

What is the inventory process?

What Is an Inventory Planning?

Inventory planning enables businesses to purchase the appropriate amount of goods and determine how frequently to replenish. Inventory planning assists in lowering the cost of stocking things and ensuring that there is sufficient stock for manufacturing and selling items. Inventory management is a significant component of supply chain management. According to research, the 80/20 rule implies that 80% of outcomes originate from 20% of efforts, customers, or another unit of measurement. When applied to inventories, the rule means that businesses generate approximately 80% of their revenues from 20% of their products.

Benefits of Inventory Planning

Inventory control and planning are two processes part of inventory management. Planning and controlling are critical to management success, as with every management process. The rationale for such a strong emphasis on inventory is that it typically represents a corporation’s most significant cash-flow component. This is true for both purchasing and selling merchandise. As a result, inventory management directly impacts the organization’s financial health. Inventory control and planning benefit small firms in the following ways:

Inventory Management Strategies

Inventory management is a highly adaptable aspect of the company. Each business has a unique inventory control strategy. However, every organization should seek to eliminate human error as much as possible from inventory management, which includes utilizing inventory management software. Regardless of the method you employ, the following will help you manage your inventory more effectively—and increase your cash flow.

1. Six Sigma

Six Sigma is a methodology and toolkit for enhancing business processes. It is used in inventory and supply chain management to minimize excess and obsolete write-offs. This inventory is frequently sold below cost or donated, which results in a loss of revenue for small business owners. Having the appropriate stock to meet demand minimizes waste and variation issues. Six Sigma is an excellent way of resolving inventory issues. It is orderly and dependable.

2. Set par levels

Set par levels for each of your goods to simplify inventory management. Par levels are the bare minimum amount of product that must always be on hand. When your inventory falls below certain specified levels, it’s time to place more orders. Ideally, you’ll order the smallest quantity necessary to return above par. Par levels vary by product and determine the speed of an item sells and the time required to restock. While establishing par levels needs some study and decision-making upfront, they will streamline the ordering process. Not only will this make decision-making more accessible for you, but it will also empower your team to make decisions on your behalf. Bear in mind that circumstances change over time. Verify par levels many times a year to ensure they remain reasonable. Meanwhile, don’t be scared to tweak your par levels upward or below.

3. FIFO

First-in, first-out (FIFO) is a critical inventory management philosophy. This means that your oldest stock is sold first (first in), not your newest store. This is critical for perishable products to avoid unsellable spoiling. Additionally, FIFO is an intelligent technique for non-perishable products. If the same boxes are constantly relegated to the back, they are more prone to wear out. Also, packaging design and functionalities frequently evolve. You don’t want to ramble up with something any longer marketable. To handle a FIFO system effectively, you’ll need a well-organized warehouse. This often entails adding fresh items from the back or otherwise ensuring that existing inventory remains initially. If you’re operating with a warehousing and fulfillment provider, they’re likely already doing this, but it’s prudent to confirm.

4. Relationship management

Successful inventory management requires the ability to adapt fast. Whether you need to return a slow-selling item to make place for a new product, swiftly replenish a high-volume seller, solve manufacturing concerns, or temporarily extend your storage space, it’s critical to maintain a solid relationship with your suppliers. In this manner, they’ll be more receptive to collaborating with you to resolve issues. Maintaining a positive relationship with your product suppliers, in particular, is critical. Frequently, minimum order amounts are negotiable. Do not be scared to request a lower minimum order quantity to avoid carrying as much inventory. A healthy connection is about more than being pleasant. It all comes down to practical, proactive communication. Notify your supplier when you anticipate a spike in sales or a high volume of purchase orders so they can adapt production accordingly. Request that they warn you when a product is running late so that you can suspend promotions or find a temporary replacement.

5. Physical inventory

A physical inventory, also known as a stock take, is the process of counting all of your goods simultaneously. After the fiscal year, many businesses do this to coincide with accounting and income tax reporting. Although physical inventories usually are performed once a year, they may be pretty disruptive to corporate operations, and they are tedious. If you do discover a disparity, it can be challenging to narrow down the source of the error when looking back over a whole year.

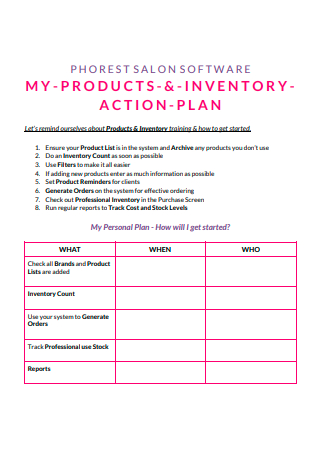

How To Develop an Inventory Action Plan

Because inventory storage is costly, businesses are frequently irritated when products collect dust on shelves rather than customers’ purchasing and generating income. While dusting the shelves adds extra effort, it’s not nearly as awful as dealing with a disgruntled customer because you’ve run out of his favorite product. Inventory stock plans are intended to avert one of these outcomes.

-

Step 1: Ascertain Demand

An intelligent inventory plan’s first rule is to stock things that customers desire and that statistics indicate are likely to be purchased. This can be determined using historical sales data, which can be obtained by tracking sales over time and logging the results in a database. Sell an average of 30 cartons of milk per day, with steady demand throughout the week. Your inventory control strategy should allow you to meet that demand while also avoiding excessive inventory. Under certain conditions, you may also wish to keep select items in stock, even if an order is weaker or less predictable. For instance, if a critical spare part for an appliance you sell is challenging to obtain promptly, stocking a limited supply can be a prudent business option. Suppose ordering that position at the last minute is prohibitively expensive, and its absence causes customers to switch providers. In that case, the storage costs may be negligible about the costs of not having it when needed.

-

Step 2: Create a Plan for Replenishment

Supply chain management is essential to the success of any inventory management strategy. Determine your reorder points, the time required for inventory to arrive, and any potential impediments. For example, a just-in-time inventory system works best when you are confident that you can obtain required goods promptly if necessary. Establish a broad replacement schedule for things you will require frequently. This could include daily deliveries of perishables to monthly shipments of non-perishables. Additionally, consider when you need stock replenishment on an Irregular Schedule and the associated costs.

-

Step 3: Maintain Inventory Control

The tracking methods of an inventory system are only as good as the system itself. Ideally, use a point-of-sale software system to catalog your inventory and track changes in real-time, and train your personnel to use it at all times. This can be difficult in a Small Firm that prepares completed items using materials from a central inventory base, such as a restaurant, but it is still necessary. Each time a customer puts an order, keep track of which ingredients go into a meal or what goes into a complete cabinet and drain those items from your inventory.

-

Step 4: Monitor and Adjust

Periodically re-examine your inventory control system to ensure that the basic assumptions remain valid. If you find that you are suddenly out of corn chips with each inventory cycle – yet have more salsa than you require – your initial demand projections may have been incorrect. Changing the order quantity for each item might help return your inventory levels to their optimal state. Developing a liquidation strategy for unsold inventory can help you move it out of storage and maximize the use of available space. For instance, end-of-season discount sales might help clear out inventory in a retail business that would otherwise linger in stock for an extended time.

FAQs

How do you keep track of your inventory?

The easiest inventory tracking method is to manually count your stock every two weeks and compare it to sales. This is referred to as periodic inventory. Additionally, perpetual inventory utilizes an inventory management app or software incorporated with your business’s point of sale system.

What is the purpose of a blind inventory count?

To begin, a blind count occurs when you send your counters out with only the item number and location information but not the quantity. They count the product and record the amount manually or with data gathering equipment.

What is the inventory process?

Stocktaking refers to the activities and procedures your business receives fresh inventory. Conducting a thorough stocktake a few times a year is critical for maintaining ideal inventory levels and reducing losses in your retail or wholesale operation.

Making inventories is difficult; imagine how difficult it is to create inventory action plans. However, taking the initial step and completing it makes subsequent activities more spontaneous and fluid. As a result, our site assists you in navigating the process of creating everything from scratch and provides you with pre-made templates that you can use as you strive to improve your inventory committee. Utilize it and let us know what you think! Additionally, we offer many organizational tools that can assist you in developing corporate systems, like a shift schedule organizer, a task checklist, and a task organizer. We also offer a variety of flyers, posters, proposals, and brochures for your advertising needs.