46+ SAMPLE Quality Control Plan

-

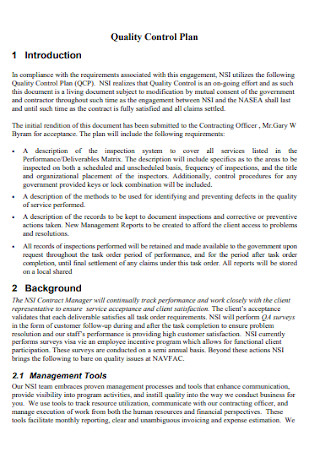

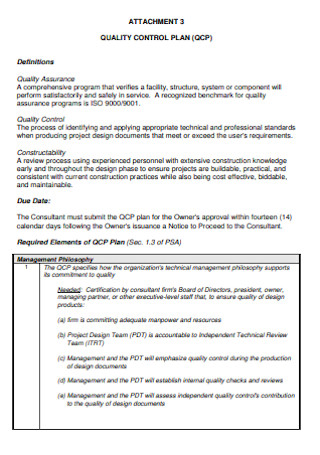

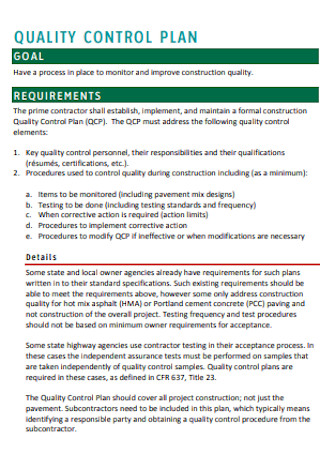

Quality Control Plan

download now -

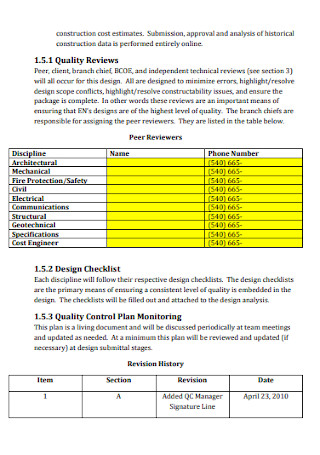

Design Quality Control Plan

download now -

Survey And Quality Control Plan

download now -

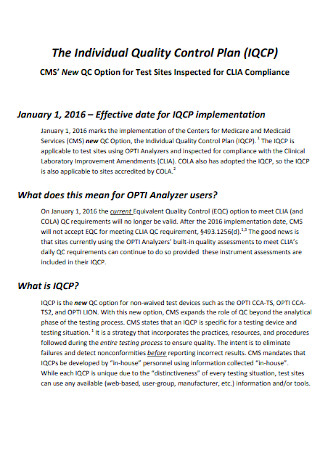

Individual Quality Control Plan

download now -

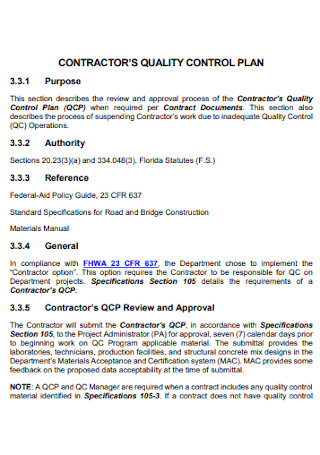

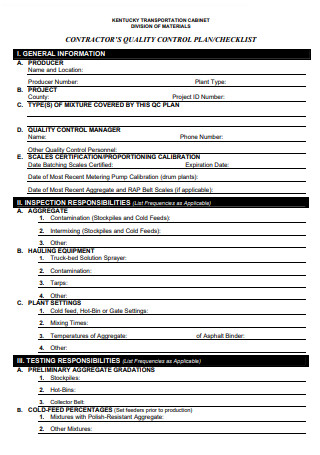

Contractor Quality Control Plan

download now -

Quality Control Plan Checklist

download now -

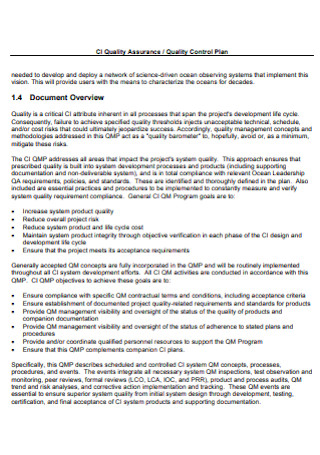

Quality Assurance and Control Plan

download now -

Sample Quality Control Plan

download now -

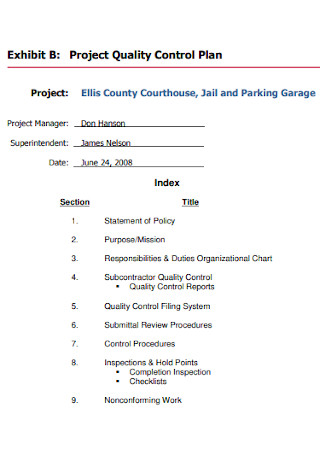

Project Quality Control Plan

download now -

Highway Safety and Quality Control Plan

download now -

Production Quality Control Plan

download now -

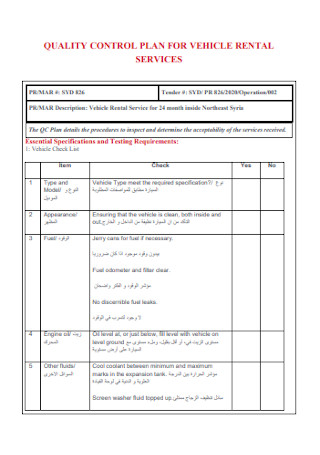

Quality Control Plan for Vehicle Rental

download now -

Quality Control Plan for Highway Bridges

download now -

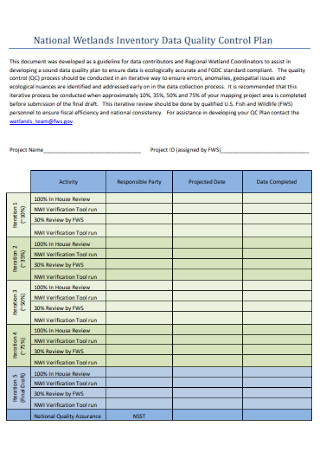

Inventory Quality Control Plan

download now -

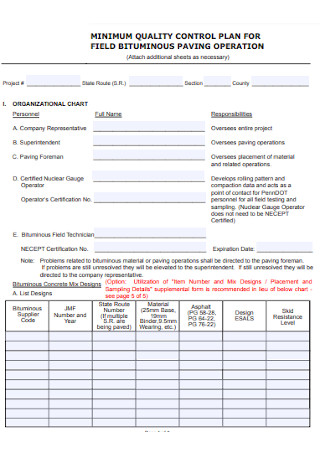

Minimum Quality Control Plan

download now -

Final Quality Control Plan

download now -

Individualized Quality Control Plan

download now -

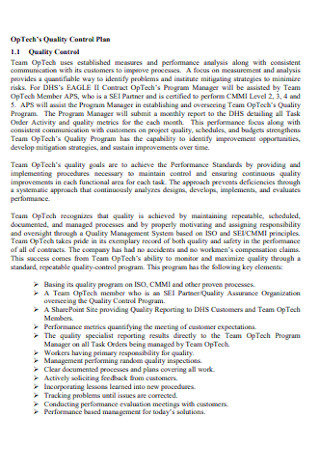

Technology Quality Control Plan

download now -

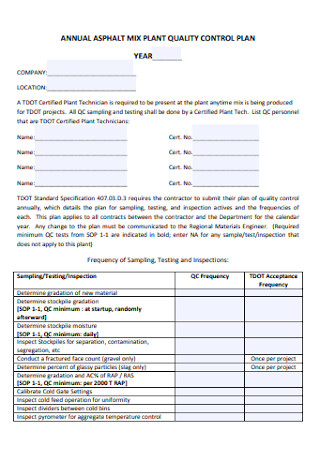

Plant Quality Control Plan

download now -

Simple Quality Control Plan

download now -

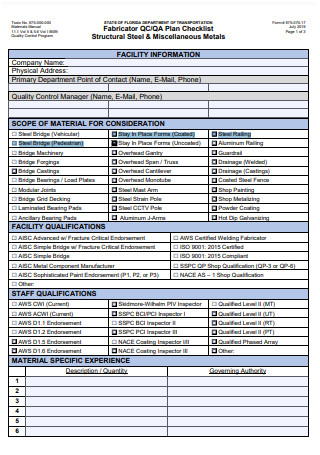

Fabricator Quality Control Plan Checklist

download now -

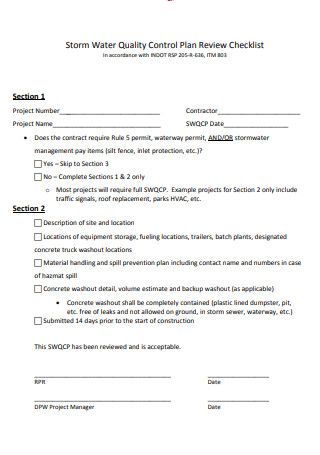

Storm Water Quality Control Plan Checklist

download now -

Contractor Quality Control Plan Checklist

download now -

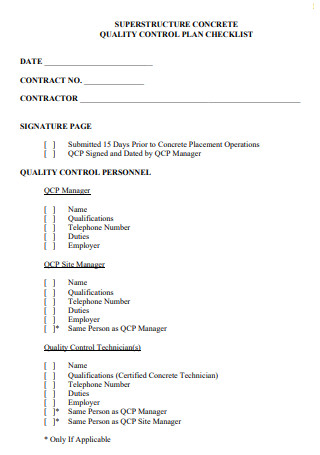

Superstructure Concrete Quality Control Plan Checklist

download now -

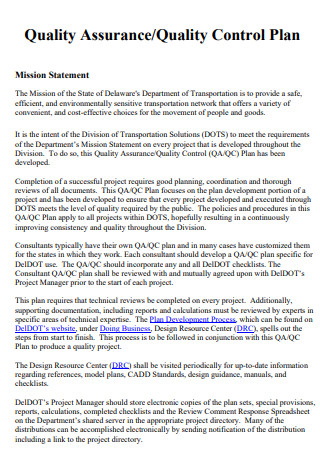

Quality Assurance Control Plan Mission Statement

download now -

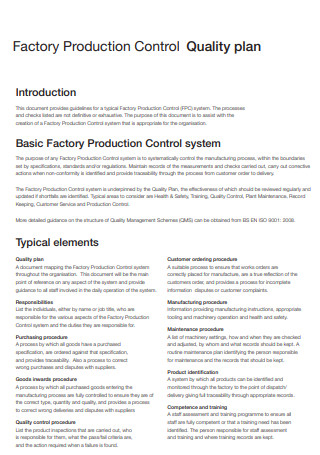

Factory Production Quality Control Plan

download now -

Quality Control Management Plan

download now -

Quality Control Technical Plan

download now -

Engineering Quality Control Plan

download now -

Design Comprehensive Quality Control Plan

download now -

Geotechnical Design Quality Control Plan

download now -

Design Bid Quality Control Plan

download now -

Quality Control Assessment Plan

download now -

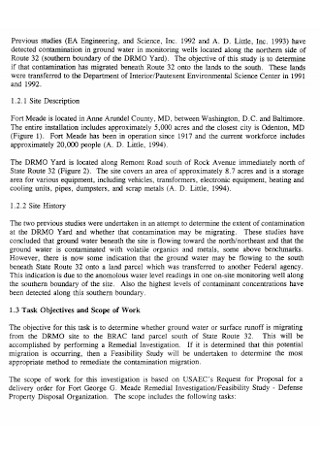

Data Quality Control Plan

download now -

Final Contractor Quality Control Plan

download now -

Spirometry Quality Control Plan

download now -

Quality Assurance Process Control Plan

download now -

Advanced Quality Control Plan

download now -

Quality Control Plan Example

download now -

Preliminary Quality Control Plan

download now -

Biodiesel Production Quality Control Plan

download now -

Quality Control Plan Template

download now -

Quality Control Plan Outlines

download now -

Integrated Quality Control Plan

download now -

General Quality Control Plan

download now -

Quality Control and Monitoring Plan

download now -

Subcontractor Quality Control Plan Outline

download now

FREE Quality Control Plan s to Download

46+ SAMPLE Quality Control Plan

What Is a Quality Control Plan?

Components of a Quality Control Plan

How To Develop an Effective Quality Control Plan

FAQs

What are the different types of quality control?

What are the four steps in the control process?

What are the three types of quality?

What Is a Quality Control Plan?

A quality control plan is a document that contains a set of procedures to deliver and produce goods that meet quality standards. Organizations use it to monitor processes, assuring consumers that necessary improvements and requirements are clear and solid over the lifecycle of the business. A quality control plan describes all the accompanying techniques, resources, and parameters that a company utilizes to satisfy the quality requirements. The document is essential for operations as it guarantees that the employees working on the production of goods have accurate information to execute the processes and methods according to industry standards. It must also have a comprehensive list of procedures to follow at the detection of conformances. The quality control plan must address policy and procedures that provide sufficient evidence of the production quality of products and services. It must also indicate the techniques and operational activities that professional and experienced employees perform to satisfy quality standards. Lastly, it must be able to represent the set of processes and rules that a business follows to cater to the expectations of the consumer market, including regulatory expectations.

According to the report of the CQ Researcher entitled Quality Control in Industry, the observation of quality control techniques range from different industries, including food production, insurance, banking, and even government industries. In 1963, the Government Employees Insurance Company or GEICO have recorded a 53 percent improvement in the quality of outgoing policies after five years of implementing quality control measures.

Components of a Quality Control Plan

The implementation of an effective quality control plan brings compliance, profitability, and the growth of a quality-driven organization. Different organizations implement quality control plans according to the industry they function in, and for life sciences institutions, certain elements must be present in the document. These core components help to identify organizational objectives and guarantee that all the necessary steps of production are compliant while monitoring opportunities for improvement. Below are the elements of a quality control plan for a business.

How To Develop an Effective Quality Control Plan

A comprehensive outline of a quality control plan streamlines the assurance procedures by providing a clear definition of protocols, employee responsibilities, and possible responses. A business needs to provide a quality control plan to guarantee the company follows standard operating procedures to satisfy customer demands. Below are six steps in creating the document.

-

1. Create an Organizational Chart

In every quality control plan, management must start with an outline of an organizational chart that includes job descriptions, business qualifications, and required training that individuals need to perform the quality assurance and control procedures. There must be documentation of these requirements that records workers performing the necessary inspections have sufficient knowledge, training, and qualifications. All these documents must be in company files in case upper management needs them to correct errors or make considerable changes.

-

2. Define Appropriate Responsibilities

Management must clearly outline all the duties and responsibilities of internal personnel and external partners in quality control measures. The parties must recognize and understand the processes and obligations of fulfilling quality checks for outputs. For many small businesses, employees are responsible for performing quality checks for their work. However, there are designated staff members that conduct quality control procedures separately. As such, there is documentation that details the adequate period of inspection to avoid any errors. In larger businesses, peer reviews are prevalent. These quality inspections and procedures must have clear definitions to prevent confusion and guarantee uniform results.

-

3. Make Material Purchases and Receipts

Before making any prior purchase of materials, management must understand the essential material specifications to adhere to quality standards. It is crucial to identify fundamental characteristics for items and equipment as locating cheap alternatives and vendors can produce products that are below industry quality standards. Upon the delivery of goods, the first step is to inspect the shipment to ensure the delivery of all items. If the materials are incomplete or are not up to par with quality standards, the company must return the items to the supplier.

-

4. Verify the Qualifications of the Supplier

Inspecting materials is relatively easy. However, when it comes to the inspection of more complex equipment or items, it can become difficult. Companies must be specific when stating their requirements and quality standards to suppliers before writing bid proposals and quotes. Most businesses search for third-party vendors to supply the company with materials following internal processes and regulations. As a result, organizations must evaluate a vendor’s credential, brand, and other qualifications for a supplier agreement.

-

5. Evaluate Quality Feedback

Receiving constructive feedback is an excellent tool for improving product quality and performance. As the primary goal of quality control is to ensure that the company produces quality products, investigating online product reviews, customer complaints, and suggestions help with identifying the strengths and weakness of products. For this, companies must introduce customer service teams to read reviews and recommendations to determine any malfunctions or damages due to non-compliance in procedures.

-

6. Develop Corrective Action Plans

As the last step, companies must compose corrective actions to resolve quality issues, including violations and non-compliance of procedures. At the filing of non-compliance, an employee responsible must verify its origin, whether it is a result of a malfunction or employee negligence. After pinpointing the issue, the company must implement corrective actions and solutions to mitigate similar scenarios from happening in the future.

FAQs

What are the different types of quality control?

There are several types and methods of performing quality control. There are four procedures prevalent in different organizations, including the x-bar chart, six sigma, 100 percent inspection mode, and the Taguchi method.

What are the four steps in the control process?

The four steps of the control process ensure the modification and appropriation of set goals as necessary. The steps start with establishing performance standards, followed by measuring actual performance, comparing standards and performance, and taking corrective actions.

What are the three types of quality?

There are three types of quality when it comes to customer satisfaction. These are basic quality, performance quality, and excitement quality.

For manufacturing and production industries, ensuring the quality of products for distribution is an essential component to achieving a large consumer market. That is why companies must construct a quality control plan to guarantee that goods are high-quality and pass through rigorous inspections and quality testing. Whether it is a start-up company or a large business, setting up quality control plans follows quality products. Create quality control plans today by downloading the samples available in the article above.