Equipment Maintenance Log Sheet Samples

-

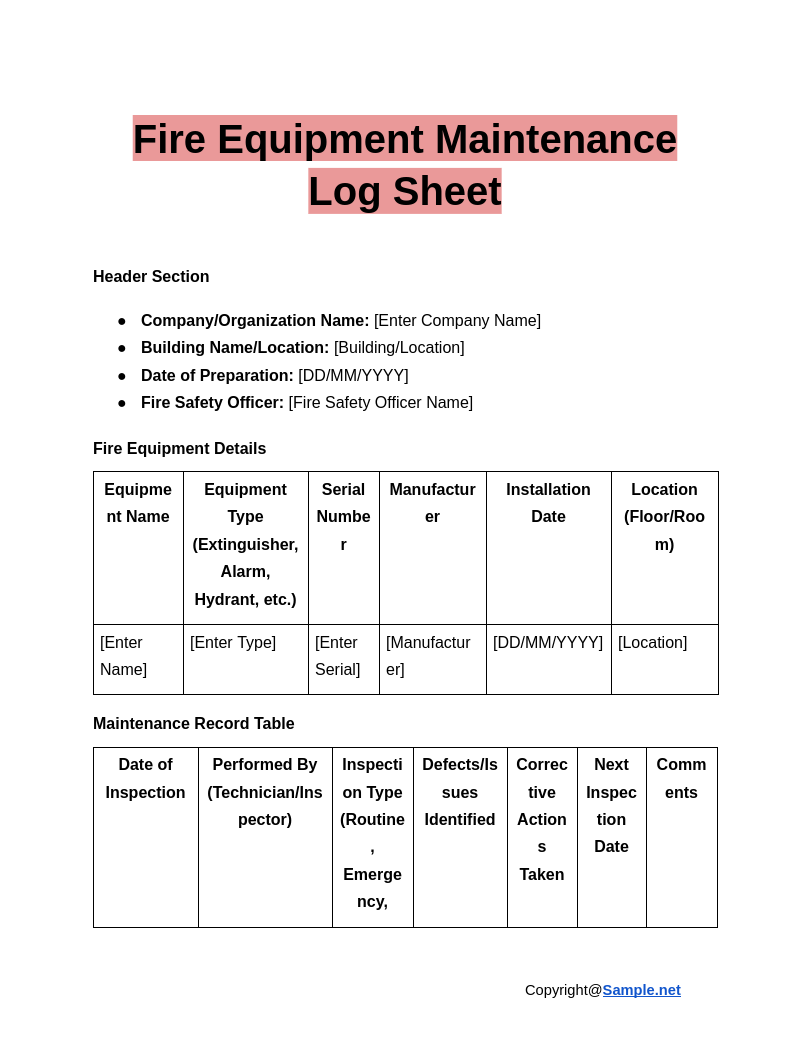

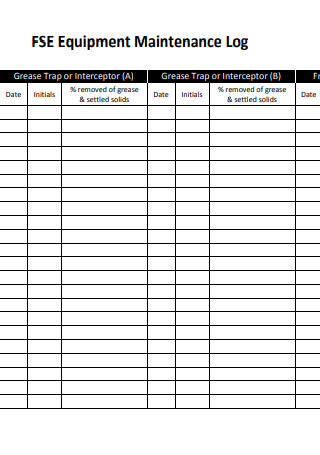

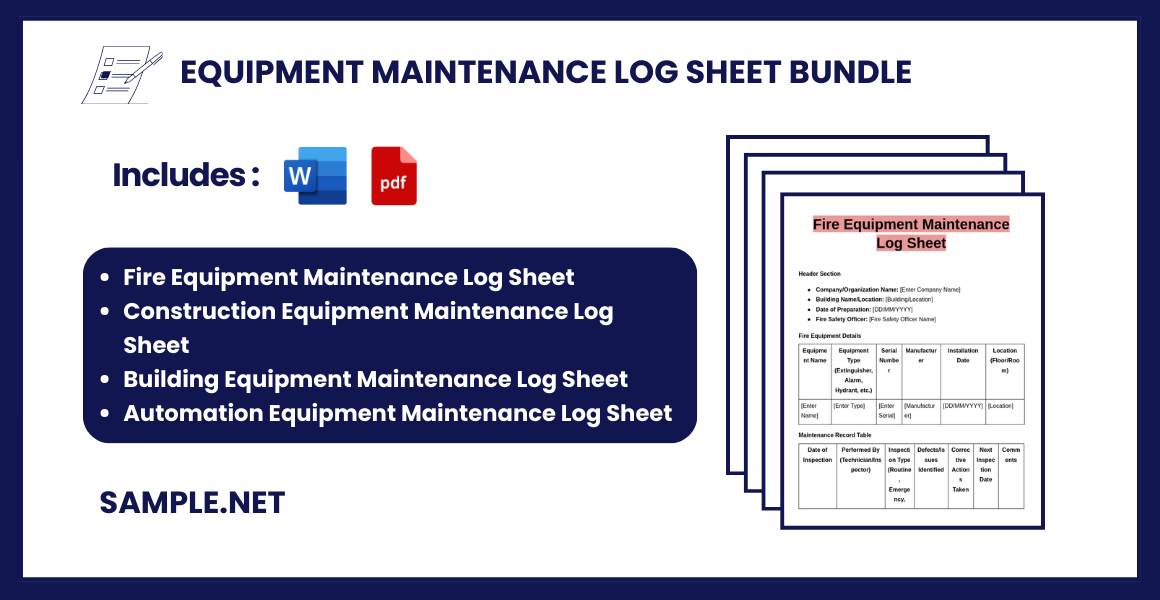

Fire Equipment Maintenance Log Sheet

download now -

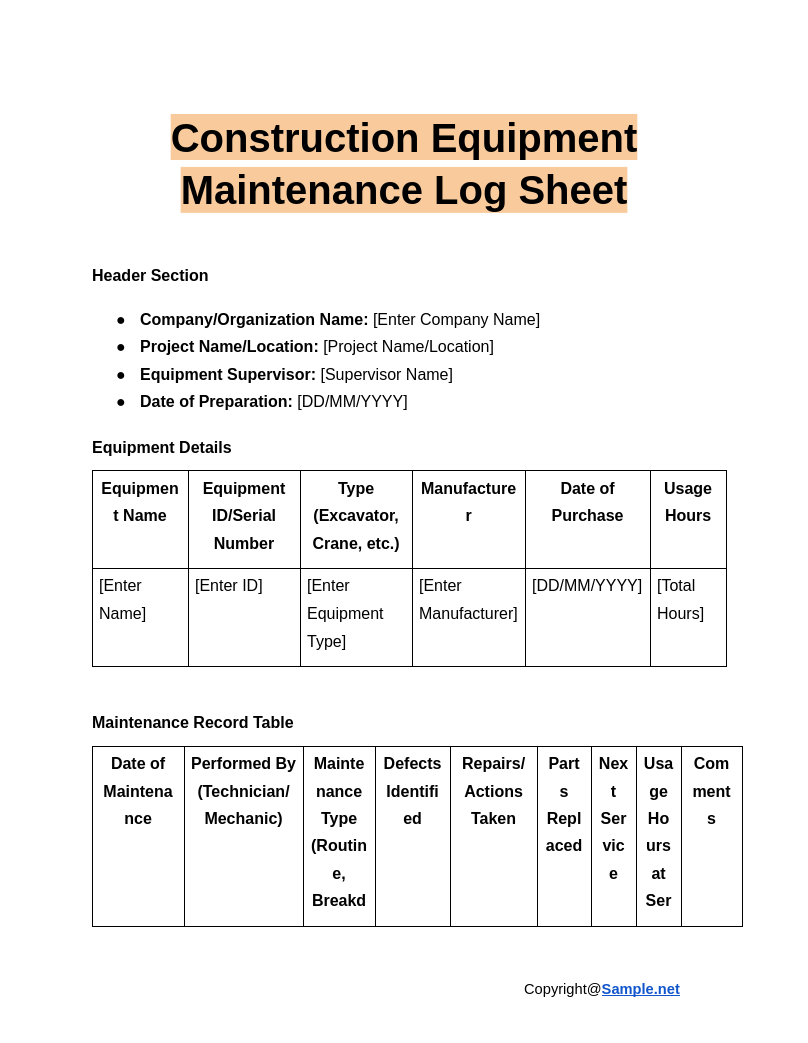

Construction Equipment Maintenance Log Sheet

download now -

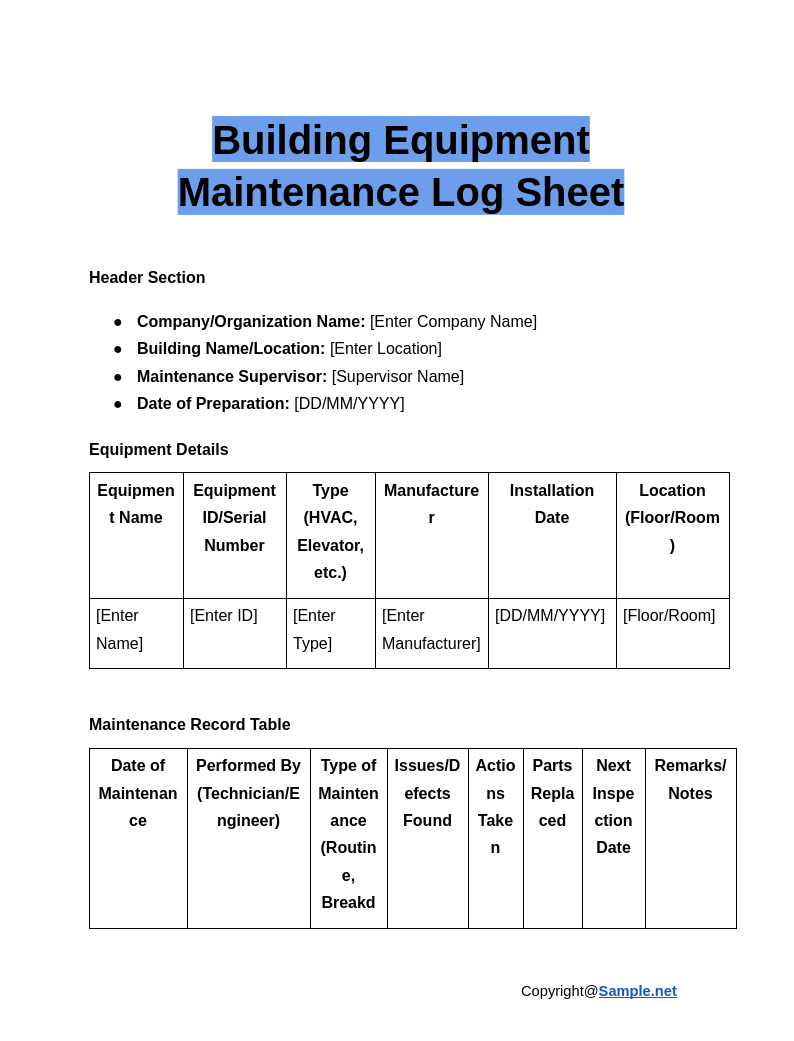

Building Equipment Maintenance Log Sheet

download now -

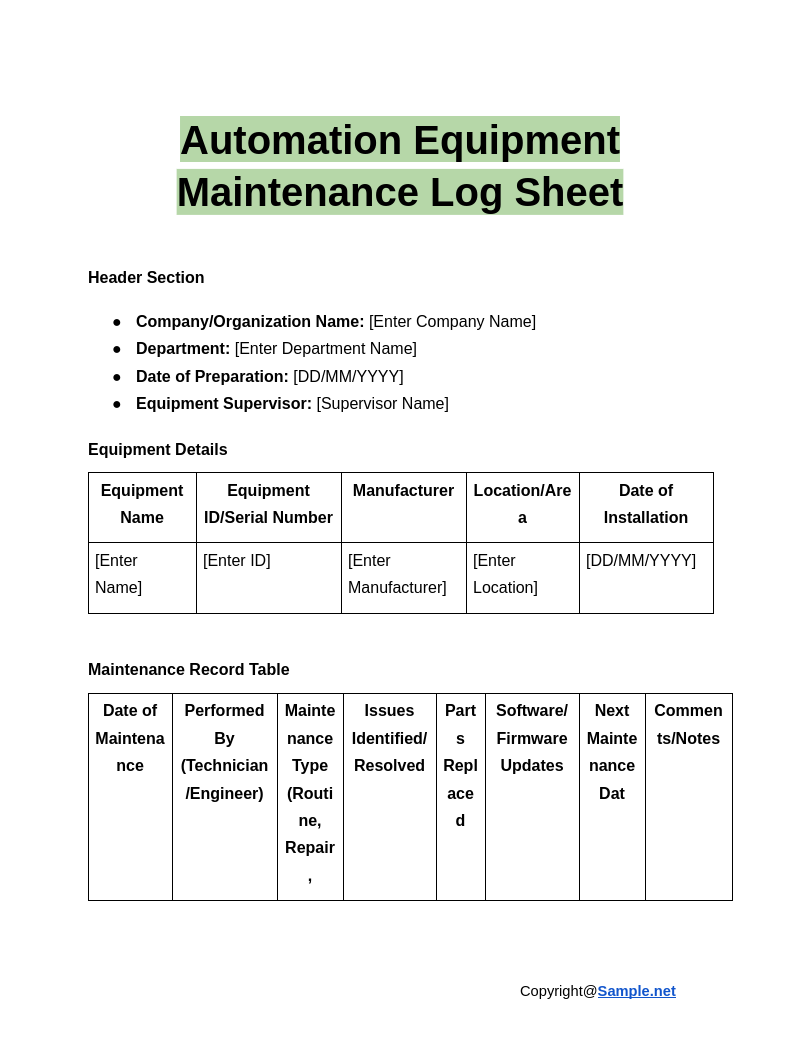

Automation Equipment Maintenance Log Sheet

download now -

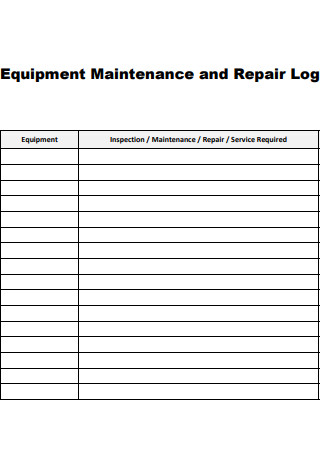

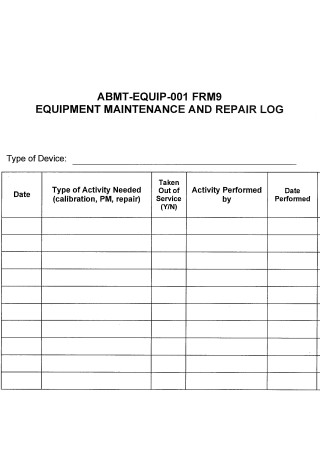

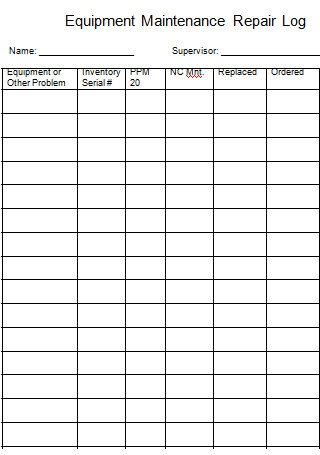

Equipment Maintenance and Repair Log Sheet

download now -

Weekly Equipment Maintenance Log Sheet

download now -

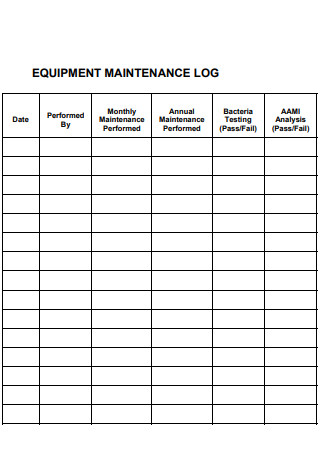

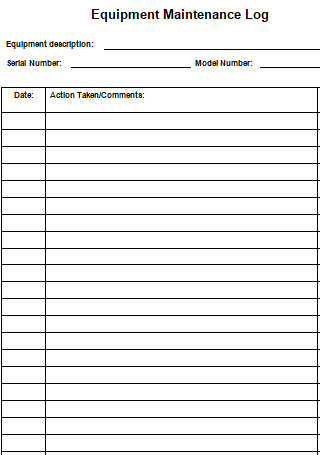

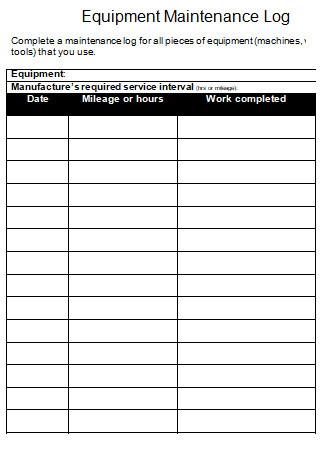

Sample Equipment Maintenance Log Sheet

download now -

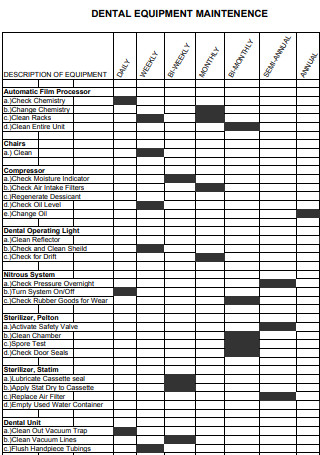

Dental Equipment Maintenance Log Sheet

download now -

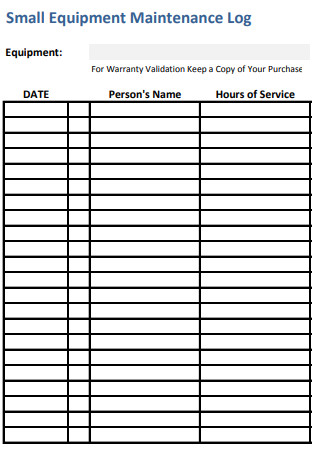

Small Equipment Maintenance Log Sheet

download now -

Standard Equipment Maintenance Log Sheet

download now -

Equipment Maintenance Log Sheet in PDF

download now -

Equipment Maintenance Log Sheet Template

download now -

Equipment Maintenance Log Sheet in DOC

download now -

Simple Equipment Maintenance Log Sheet

download now -

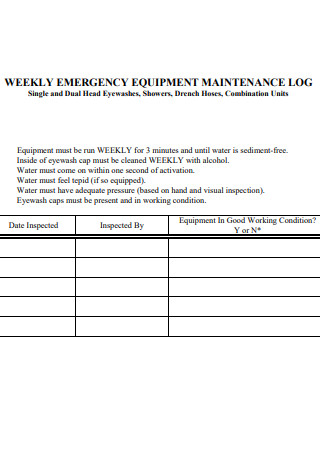

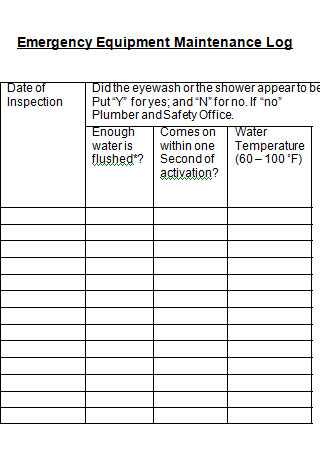

Emergency Equipment Maintenance Log Sheet

download now -

Equipment Maintenance Log Sheet Example

download now -

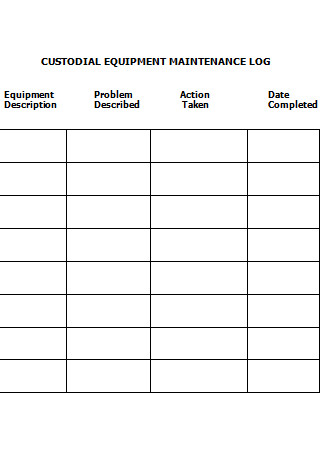

Basic Equipment Maintenance Log Sheet

download now -

General Equipment Maintenance Log Sheet

download now

FREE Equipment Maintenance Log Sheet s to Download

Equipment Maintenance Log Sheet Format

Equipment Maintenance Log Sheet Samples

What is an Equipment Maintenance Log Sheet?

What Are the Parts of an Equipment Maintenance Log Sheet?

What are the Benefits of Using an Equipment Maintenance Log Sheet?

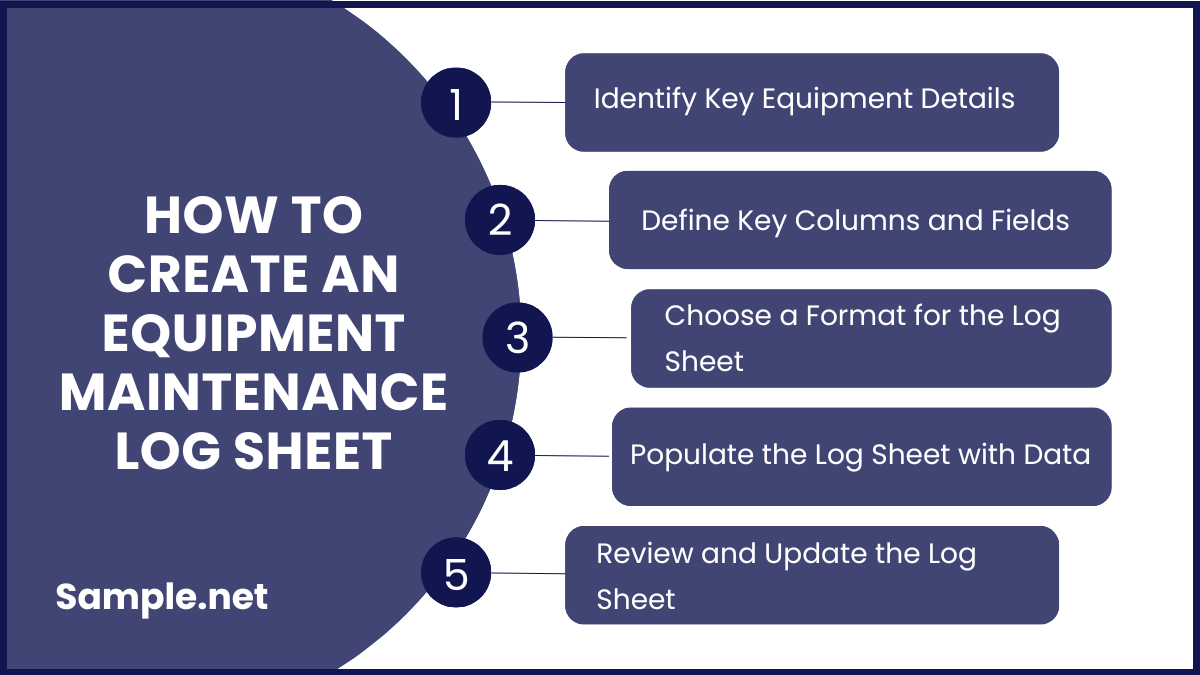

How to Create an Equipment Maintenance Log Sheet

FAQs

What is a CMMS?

How to keep your Equipment Maintenance Log Sheet updated?

What are Maintenance Procedures?

What information should be included in a maintenance log sheet?

What are the consequences of not maintaining an Equipment Maintenance Log Sheet?

How do you ensure the accuracy of information in a maintenance log sheet?

Download Equipment Maintenance Log Sheet Bundle

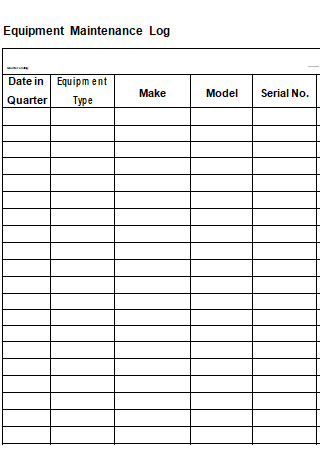

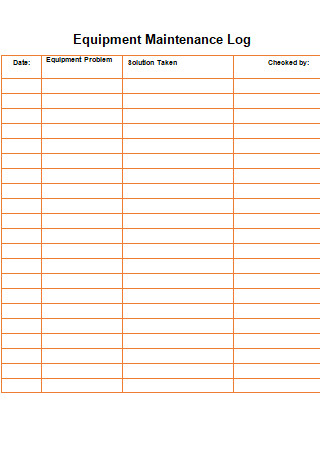

Equipment Maintenance Log Sheet Format

1. Header Section

- Company/Organization Name: [Enter Company Name]

- Department: [Enter Department Name]

- Prepared By: [Name of Person Responsible]

- Date of Preparation: [DD/MM/YYYY]

2. Equipment Details

| Equipment Name | Equipment ID/Serial Number | Model/Type | Location | Date of Purchase |

|---|---|---|---|---|

| [Enter Name] | [Enter ID] | [Enter Model] | [Enter Location] | [Enter Date] |

3. Maintenance Record Table

| Date of Maintenance | Performed By (Technician/Engineer) | Type of Maintenance (Preventive, Corrective, Routine) | Tasks Performed/Issues Identified | Parts Replaced | Next Maintenance Date | Comments/Remarks |

|---|---|---|---|---|---|---|

| [DD/MM/YYYY] | [Technician Name] | [Type of Maintenance] | [List of tasks/issues] | [Parts, if any] | [Next Date] | [Additional Notes] |

| [DD/MM/YYYY] | [Technician Name] | [Type of Maintenance] | [List of tasks/issues] | [Parts, if any] | [Next Date] | [Additional Notes] |

| [DD/MM/YYYY] | [Technician Name] | [Type of Maintenance] | [List of tasks/issues] | [Parts, if any] | [Next Date] | [Additional Notes] |

4. Maintenance Summary

| Total Maintenance Hours | Number of Repairs | Number of Replacements | Overall Equipment Condition (Good, Fair, Poor) |

|---|---|---|---|

| [Total Hours] | [No. of Repairs] | [No. of Replacements] | [Condition] |

5. Sign-off Section

- Prepared By (Name, Position, Signature): _________________________

- Reviewed/Approved By (Name, Position, Signature): _________________________

- Date of Review/Approval: [DD/MM/YYYY]

What is an Equipment Maintenance Log Sheet?

An Equipment Maintenance Log Sheet is a structured document used to track and record maintenance activities for machinery, tools, and other equipment. It contains essential details like the equipment name, date of service, nature of the maintenance, responsible personnel, and next service date. This log sheet helps businesses maintain a systematic approach to equipment care, reduce downtime, and ensure that all maintenance activities are performed on time. It’s an essential document for industries relying on heavy machinery and technical equipment. You can also see more on Equipment Calibration Logs.

What Are the Parts of an Equipment Maintenance Log Sheet?

Here are the two main parts of an equipment maintenance log sheet; these may vary by company.

- Header – It provides information about the equipment which includes, the equipment name, serial number, plant location, manufacturer, the manufacturer part number, manufacturer contact details, the date of manufacturing, and the date of service.

- Entries – This is the second main part of the log sheet and allows the entry of the various maintenance activities being performed on the equipment. Here, the details about the activity are listed, such as the date when it was performed, the description of the activity, and the person who performed the said activity. You can also see more on Cleaning Log.

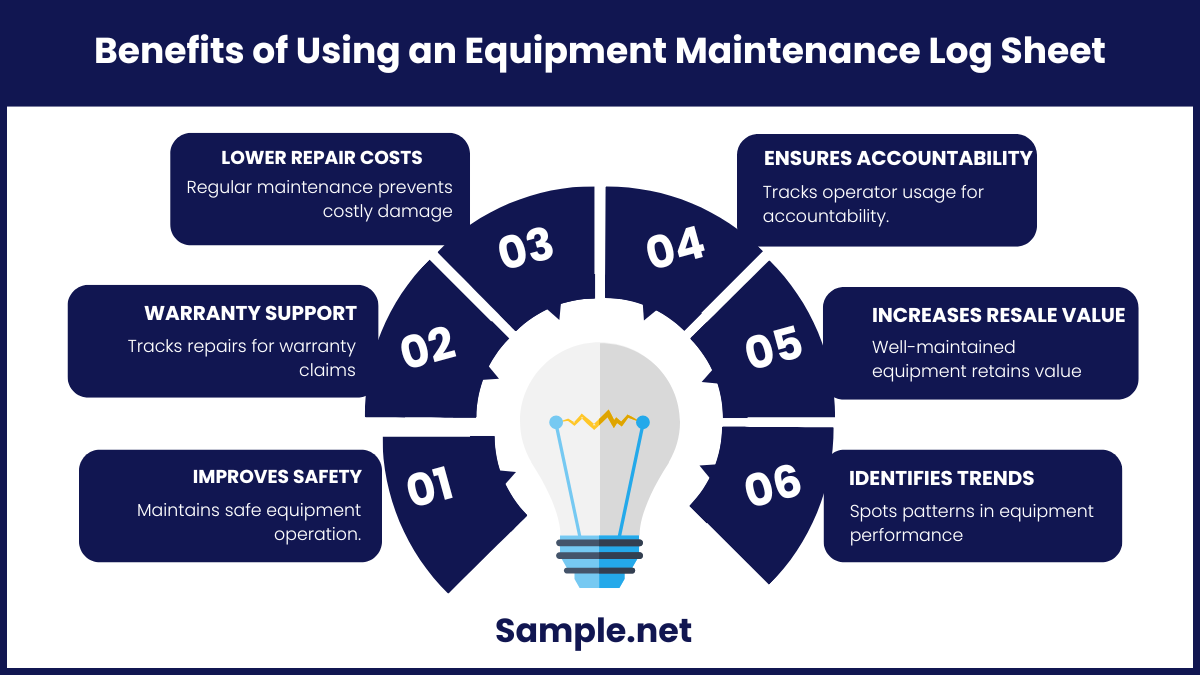

What are the Benefits of Using an Equipment Maintenance Log Sheet?

A company that is dedicated to taking care of its equipment will always have a good maintenance log sheet. There are numerous benefits to using one, and here are some of them:

How to Create an Equipment Maintenance Log Sheet

Step 1: Identify Key Equipment Details

Start by listing all the equipment that requires maintenance tracking. Include details like equipment name, unique identification number, and model. This will ensure each piece of equipment is easily identifiable in the log sheet.

Step 2: Define Key Columns and Fields

Create essential columns for the log sheet. These may include the date of maintenance, type of service performed, issues identified, parts replaced, service provider, and the next scheduled maintenance date. Custom fields can also be added as per industry-specific needs. You can also see more on Donation Logs.

Step 3: Choose a Format for the Log Sheet

Decide whether you want the log sheet to be in paper format, a spreadsheet, or digital form using maintenance software. Digital formats are preferred as they enable real-time updates and easier data access.

Step 4: Populate the Log Sheet with Data

Record past maintenance history, upcoming maintenance schedules, and equipment details. Ensure accurate data entry to maintain a reliable and consistent maintenance record. Keep track of the person responsible for each maintenance task.

Step 5: Review and Update the Log Sheet Periodically

Establish a process for regular updates and audits of the log sheet. Ensure that maintenance records are reviewed monthly or quarterly to avoid data errors and ensure compliance. Conduct inspections and cross-check that all entries are correct. You can also see more on Tracking Logs.

An Equipment Maintenance Log Sheet is a crucial document for tracking equipment servicing, ensuring efficiency, and preventing equipment failure. It helps businesses maintain smooth operations and extends the life of critical equipment. By using a structured log sheet, companies can avoid costly breakdowns, ensure regulatory compliance, and keep machinery in peak condition. Whether it’s daily, weekly, or monthly logs, this document is essential for industries that rely on equipment for continuous production and operational efficiency. You can also see more on Business Log.

FAQs

What is a CMMS?

A computerized maintenance management system refers to a type of software that centralizes maintenance information and facilitates the process of maintenance operations. It helps optimize the utilization and availability of physical equipment such as vehicles, machinery, communications, plant infrastructures, and other types of assets. These systems can be found in manufacturing, oil and gas production, power generation, construction, and any other types of industries where physical infrastructure is of critical use.

How to keep your Equipment Maintenance Log Sheet updated?

The best method to keep your maintenance log sheet updated is by using a CMMS. This enables the data to be interconnected. While data is encoded in the CMMS only once, it is used in multiple places. To ensure that the data being shared across multiple places is accurate, a good practice would be entering it in a consistent format. However, if you’re still on the manual method of pen and paper, a good practice would be to make a standardized template for each and every asset that you want to track and try to keep these templates as similar as possible. It is also important to have a designated place for where the records are to be kept and to define how the maintenance logs should change hands during a change of shift. You can also see more on Research Log.

Above everything else, the best practice to keep the maintenance log updated regardless of whether you’re using a CMMS or still on the manual approach is by paying attention to the need for accurate communication of the importance of accurate data entry.

What are Maintenance Procedures?

Maintenance procedures refer to a set of detailed instructions for doing maintenance tasks. Maintenance procedures must be up to date and easily accessible so that the maintenance personnel can follow them precisely. This ensures the reliability and good performance of the equipment.

What information should be included in a maintenance log sheet?

A maintenance log sheet typically includes the date of service, equipment name, service type, issues resolved, parts replaced, and the next service date. Custom fields can be added based on industry needs. You can also see more on Teacher Log.

What are the consequences of not maintaining an Equipment Maintenance Log Sheet?

Failure to maintain an Equipment Maintenance Log Sheet can result in missed service deadlines, unplanned equipment breakdowns, and higher repair costs. Without a proper record, it becomes difficult to prove maintenance compliance during audits. Downtime due to equipment failure can negatively impact productivity and profitability.

How do you ensure the accuracy of information in a maintenance log sheet?

Accuracy can be ensured by training staff on how to fill out the log sheet correctly. Verification should be done periodically by supervisors or maintenance managers. Using digital software with automated data tracking also minimizes the risk of human error. You can also see more on Parent Contact Logs.