Equipment Checklist Samples

-

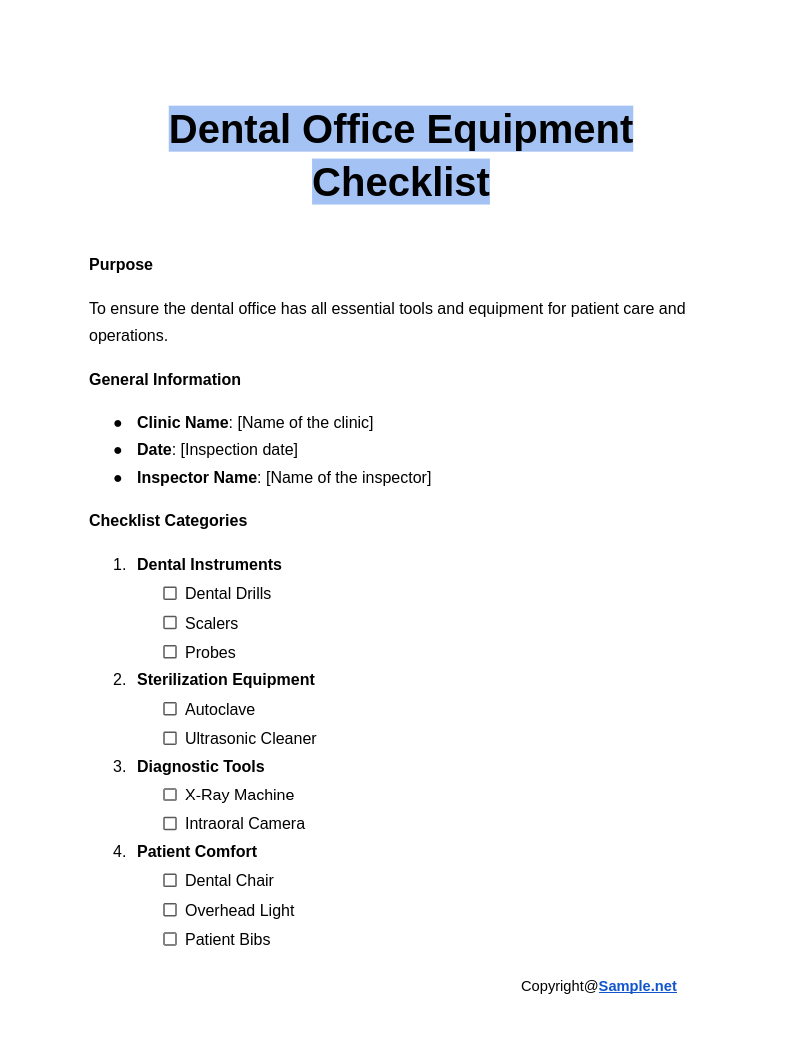

Dental Office Equipment Checklist

download now -

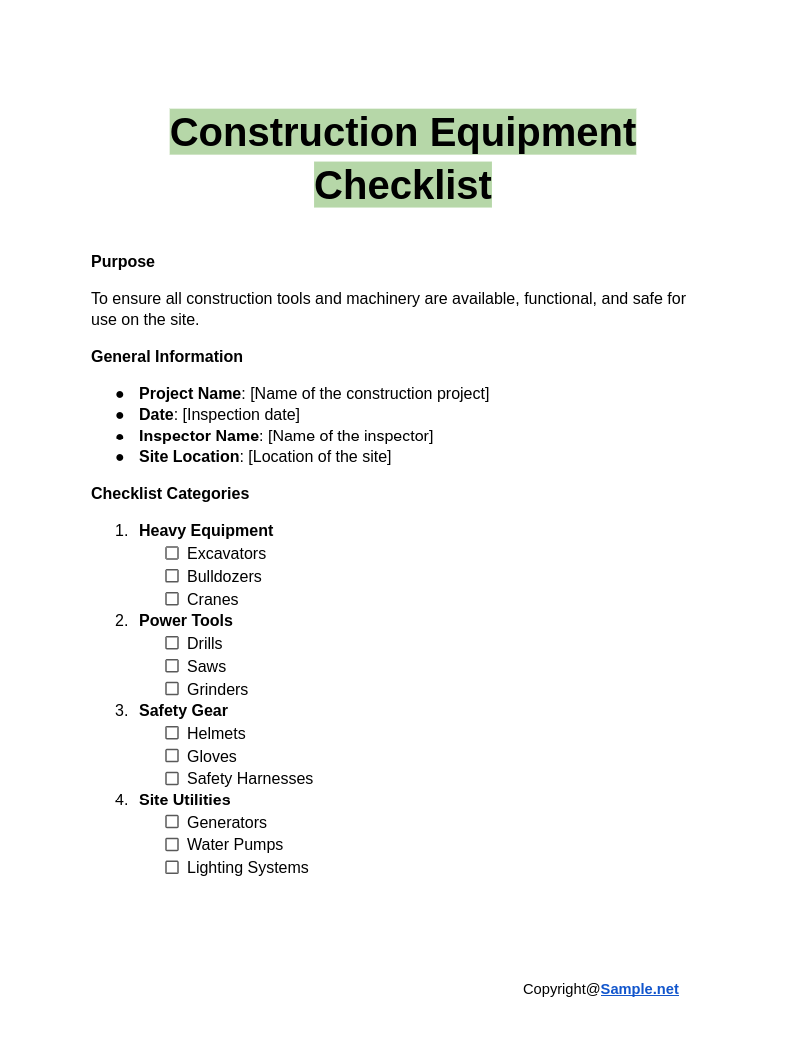

Construction Equipment Checklist

download now -

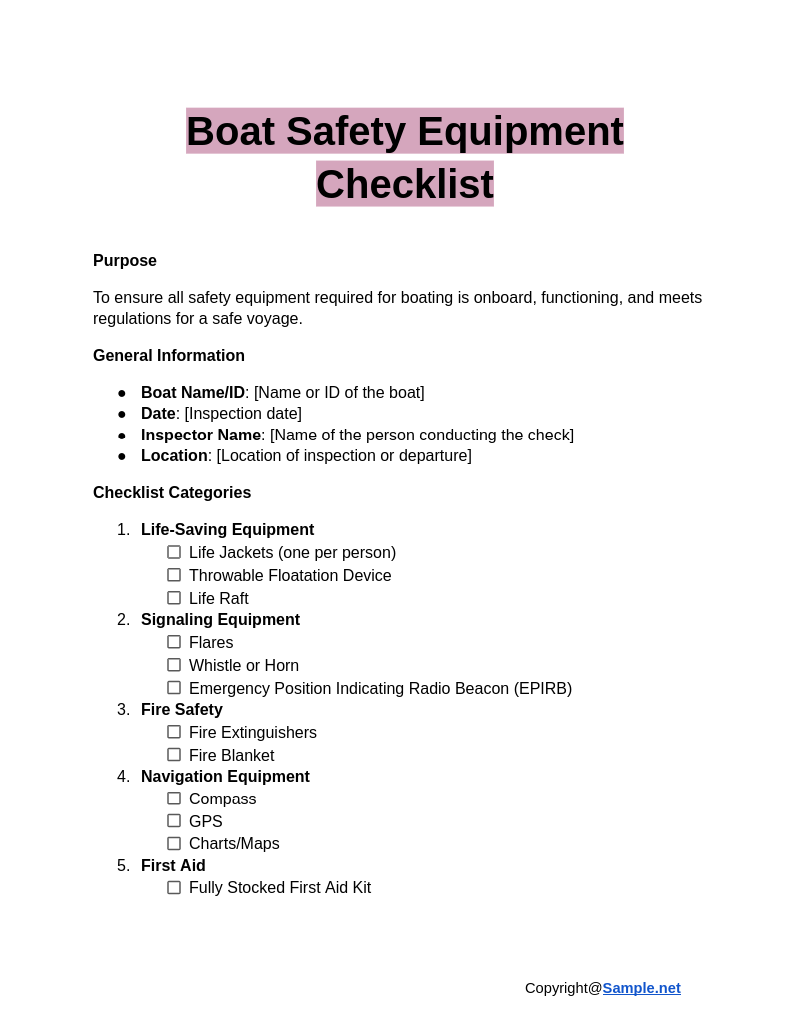

Boat Safety Equipment Checklist

download now -

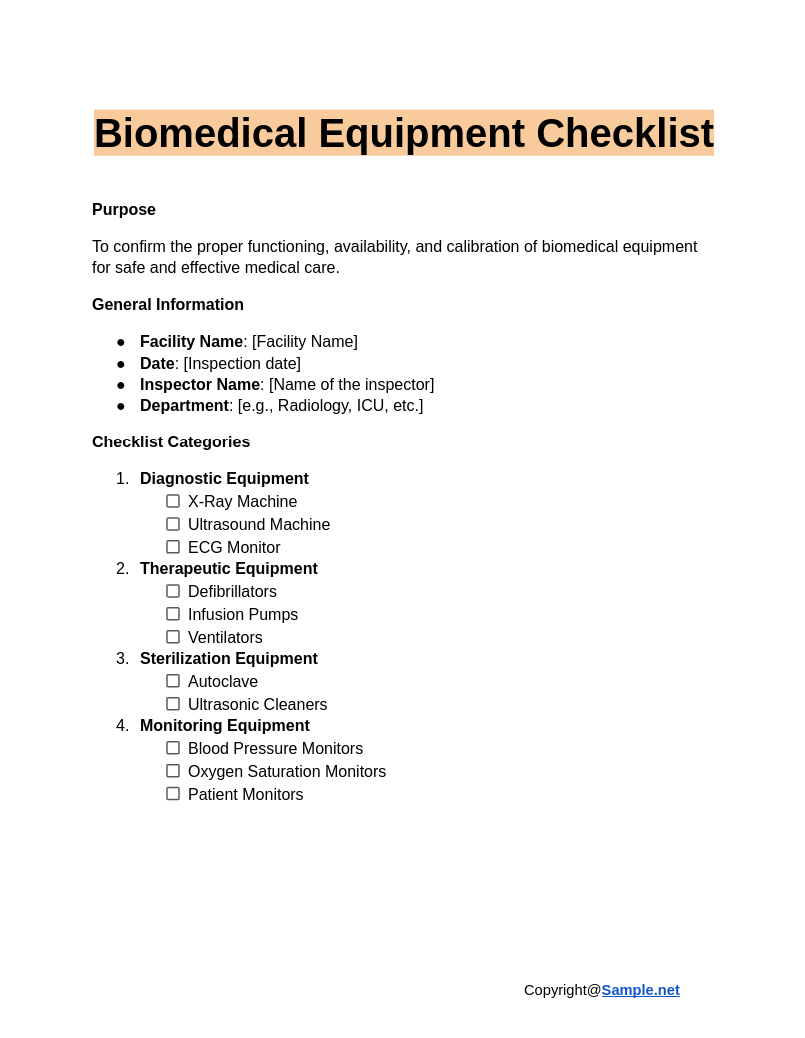

Biomedical Equipment Checklist

download now -

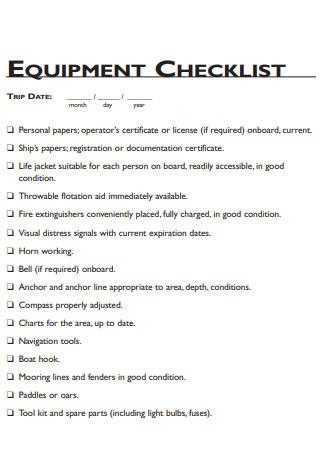

Equipment Checklist

download now -

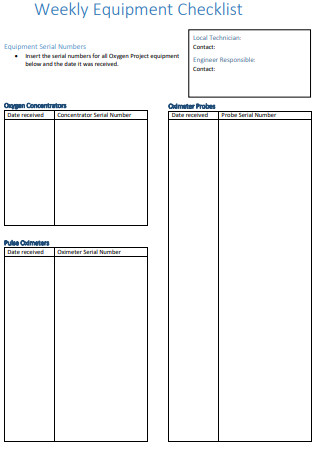

Weekly Equipment Checklist

download now -

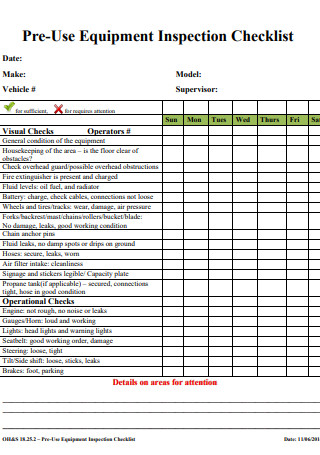

Pre-Use Equipment Inspection

download now -

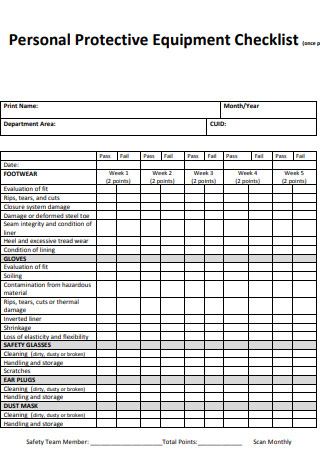

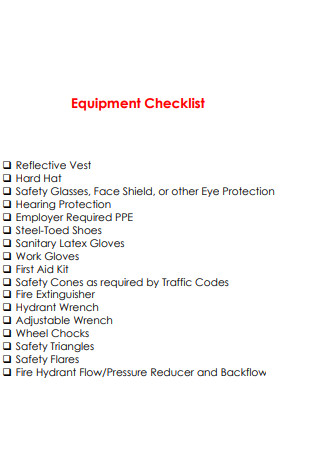

Personal Protective Equipment Checklist

download now -

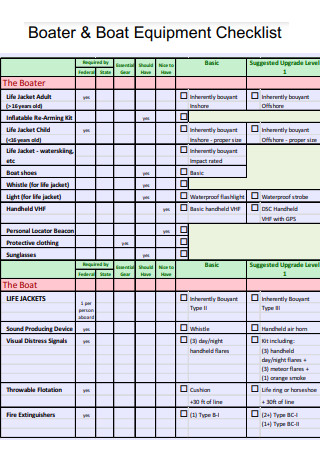

Boater & Boat Equipment Checklist

download now -

Equipment Maintenance Checklist

download now -

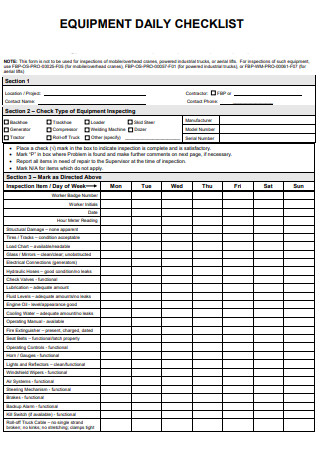

Equipment Daily Checklist

download now -

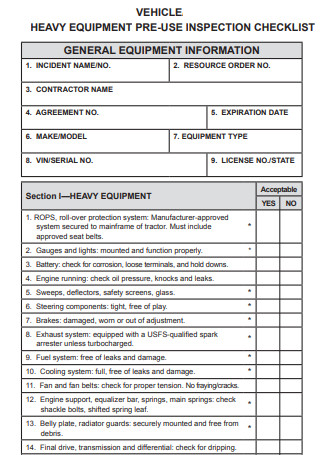

Vehicle Equipment Pre Use Inspection Checklist

download now -

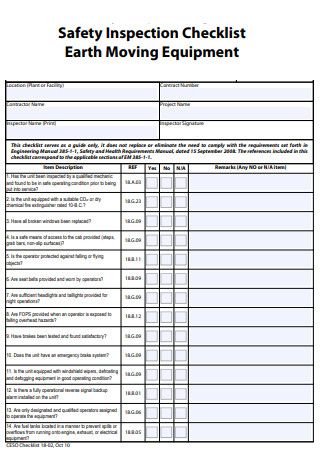

Earth Moving Equipment Checklist

download now -

Fixed Equipment Checklist

download now -

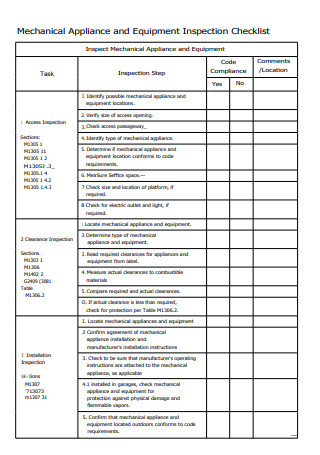

Mechanical Appliance and Equipment Inspection Checklist

download now -

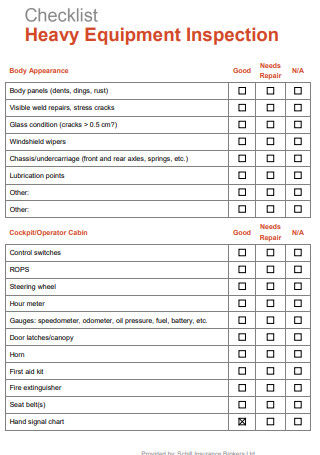

Heavy Equipment Inspection Checklist

download now -

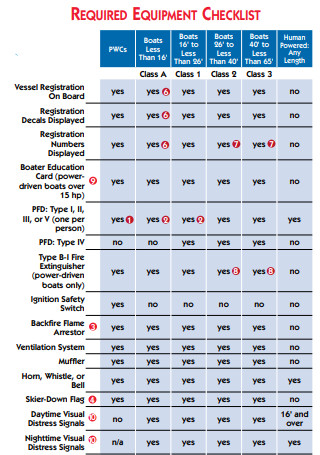

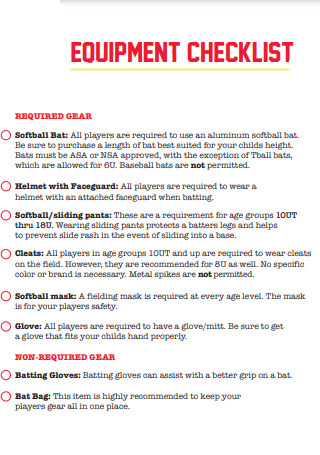

Required Equipment Checklist

download now -

Equipment and Inventory Review Checklist

download now -

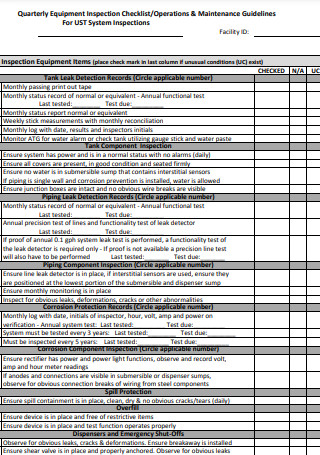

Quarterly Equipment Inspection Checklist

download now -

Personal Equipment Checklist

download now -

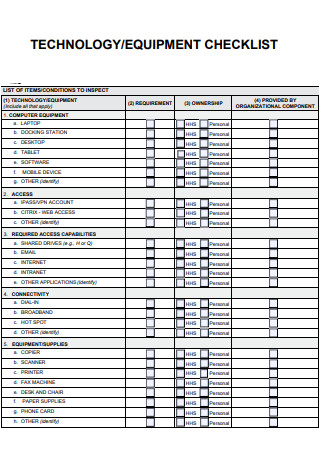

Technology Equipment Checklist

download now -

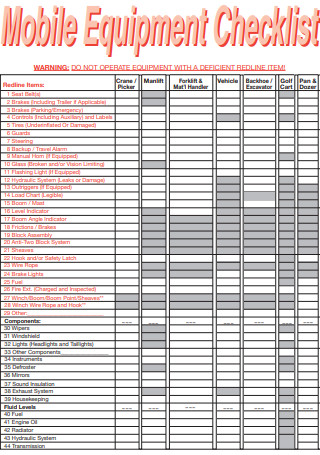

Mobile Equipment Checklist

download now -

Equipment and Machine Safety Checklist

download now -

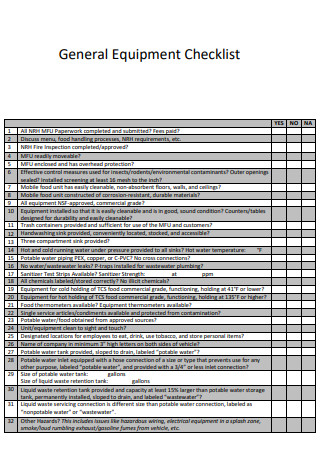

General Equipment Checklist

download now -

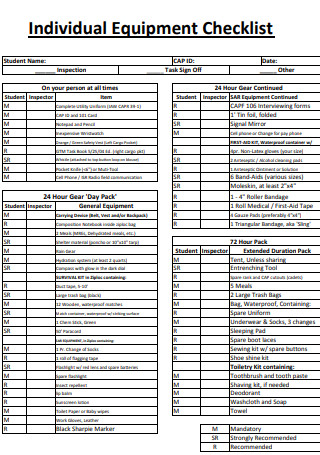

Individual Equipment Checklist

download now -

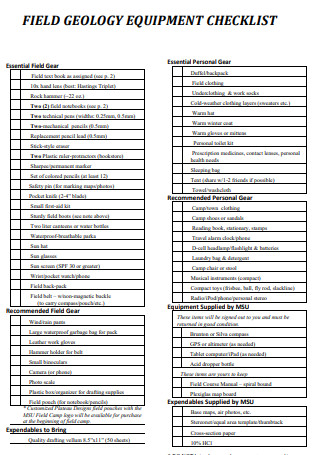

Geology Equipment Checklist

download now -

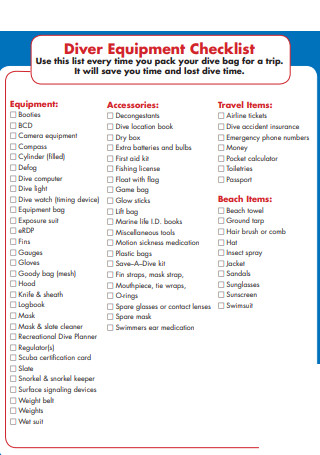

Diver Equipment Checklist

download now -

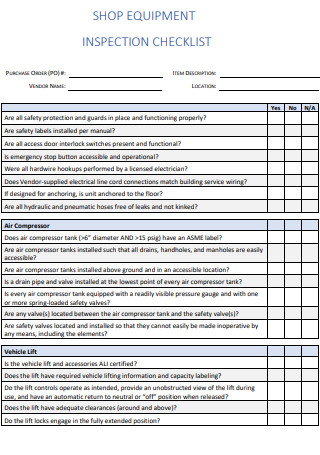

Shop Equipment Checklist

download now -

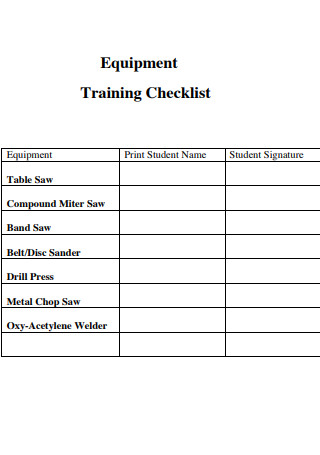

Equipment Training Checklist

download now -

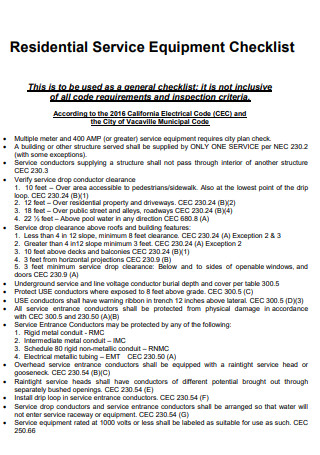

Residential Service Equipment Checklist

download now -

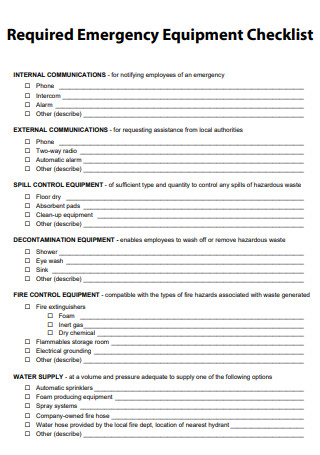

Required Emergency Equipment Checklist

download now -

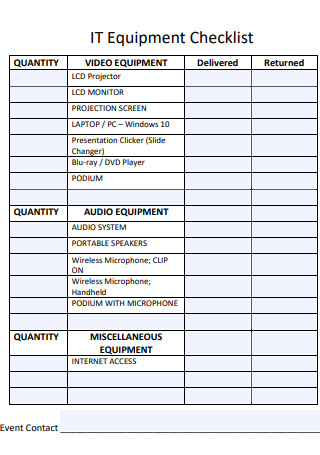

IT Equipment Checklist

download now -

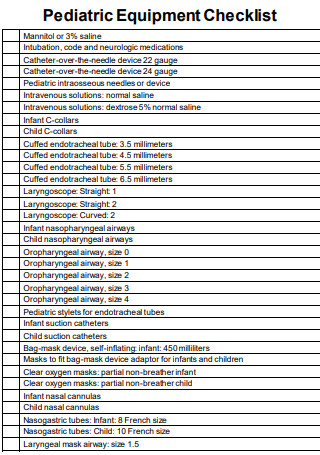

Pediatric Equipment Checklist

download now -

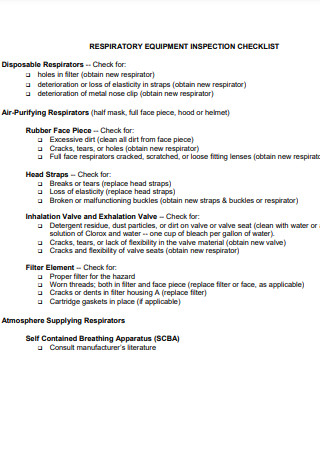

Respiratory Equipment Inspection Checklist

download now -

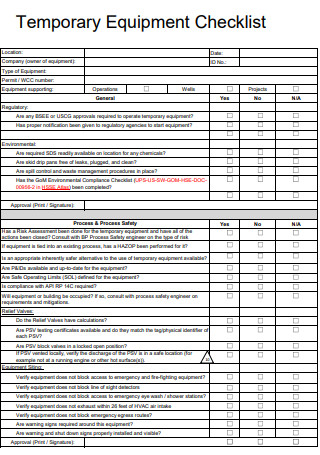

Temporary Equipment Checklist

download now -

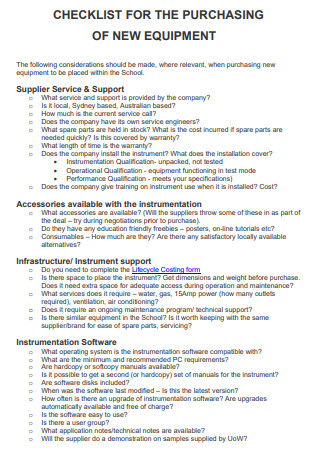

New Equipment Checklist

download now -

Refrigerated Equipment Checklist

download now -

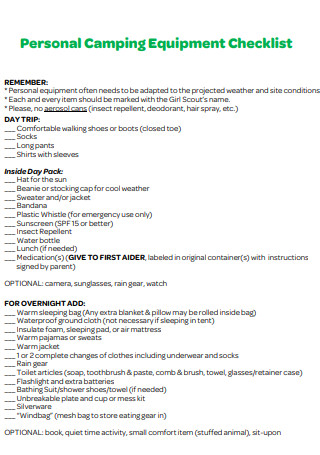

Personal Camping Equipment Checklist

download now -

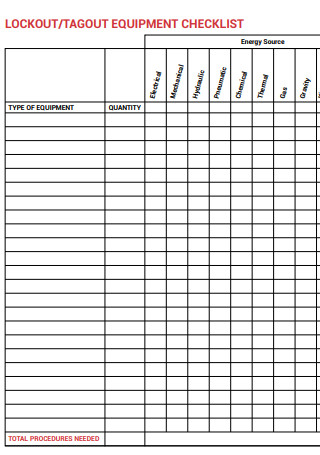

Tagout Equipment Checklist

download now -

Equipment Payment Checklist

download now -

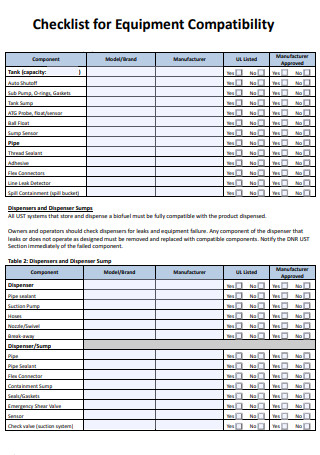

Equipment Compatibility Checklist

download now -

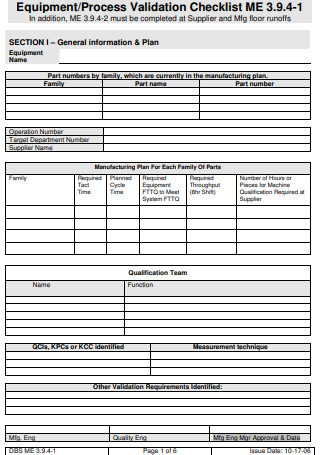

Equipment Process Validation Checklist

download now -

Machinery and Equipment Checklist

download now -

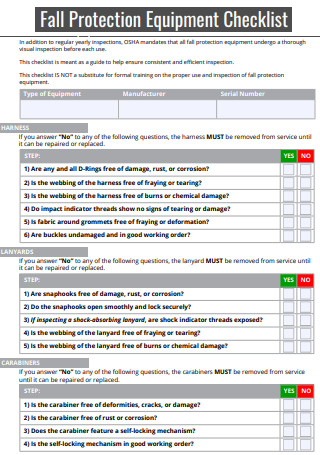

Fall Protection Equipment Checklist

download now -

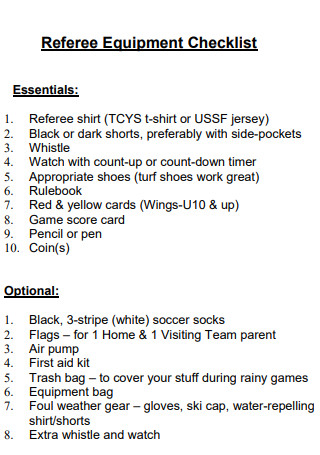

Referee Equipment Checklist

download now -

Building Systems and Equipment Checklist

download now -

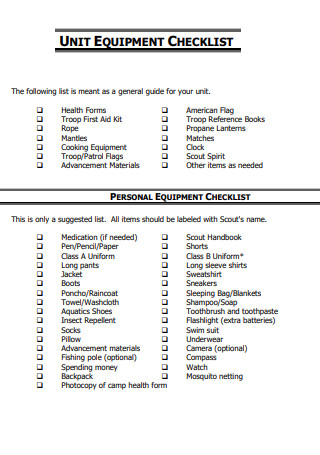

Unit Equipment Checklist

download now -

String Instrument and Equipment Checklist

download now -

Sample Equipment Checklist

download now -

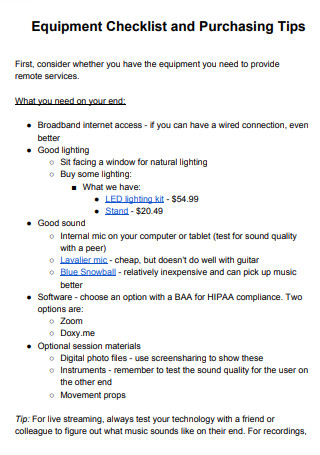

Equipment Checklist and Purchasing Tips

download now -

New Employee Equipment Checklist

download now -

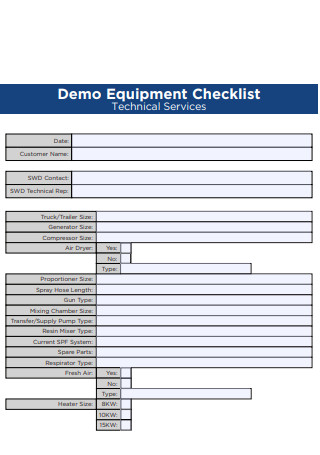

Demo Equipment Checklist

download now -

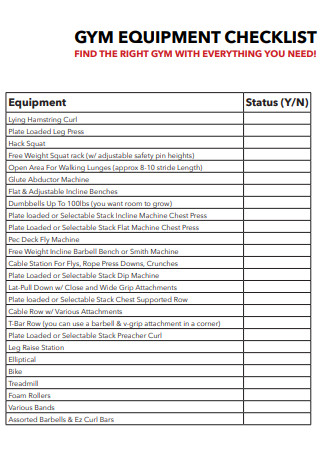

Gym Equipment Checklist

download now -

Standard Equipment Checklist

download now -

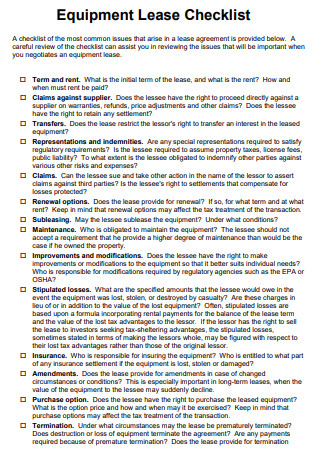

Equipment Lease Checklist

download now

FREE Equipment Checklist s to Download

Equipment Checklist Format

Equipment Checklist Samples

an Equipment?

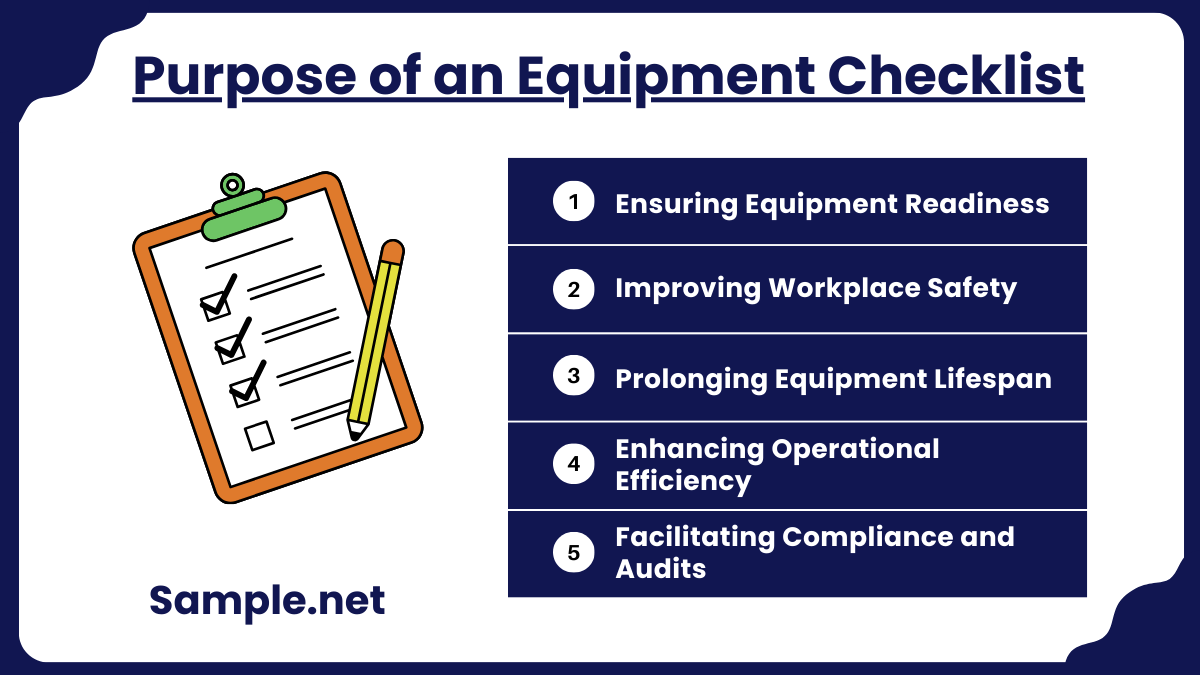

Purpose of an Equipment Checklist

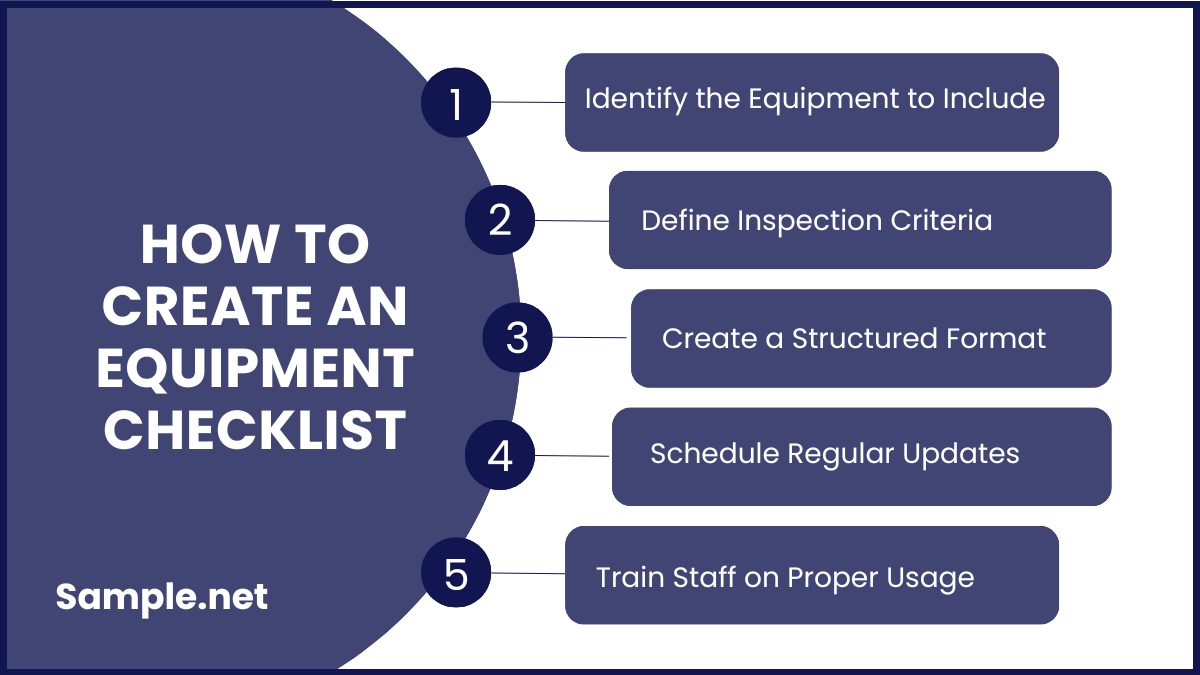

How to Create an Equipment Checklist

FAQs

What is the definition of a checklist format?

What is the definition of a basic checklist?

What purpose does a checklist serve?

What industries benefit the most from Equipment Checklists?

What role does an Equipment Checklist play in audits?

How can digital Equipment Checklists improve efficiency?

What happens if equipment fails despite using a checklist?

Download Equipment Checklist Bundle

Equipment Checklist Format

Purpose

- Clearly define the purpose of the checklist, e.g., “To ensure all necessary equipment is prepared for [specific activity/project].”

General Information

- Activity/Event Name: [Name of the project, activity, or event]

- Date: [Date of the activity/event]

- Location: [Location where equipment will be used]

- Responsible Person: [Name or role responsible for overseeing the equipment]

Checklist Categories

Divide equipment into categories for better organization. Examples:

- Safety Equipment

- [Item 1]

- [Item 2]

- [Item 3]

- Tools & Instruments

- [Item 1]

- [Item 2]

- [Item 3]

- Communication Devices

- [Item 1]

- [Item 2]

- [Item 3]

- Consumables & Supplies

- [Item 1]

- [Item 2]

- [Item 3]

- Miscellaneous Items

- [Item 1]

- [Item 2]

- [Item 3]

Checklist Table (Optional)

Create a table for quick marking:

| Item | Quantity Required | Quantity Packed | Condition | Comments |

|---|---|---|---|---|

| Safety Goggles | 10 | Good/Replace | ||

| Walkie-Talkies | 5 | Good/Needs Battery | ||

| First Aid Kit | 1 | Complete/Incomplete |

Additional Notes

- [Write any additional notes, reminders, or specific instructions.]

Boat Safety Equipment Checklist

Biomedical Equipment Checklist

Construction Equipment Checklist

Dental Office Equipment Checklist

What is an Equipment?

An Equipment Checklist is a structured document that helps track, monitor, and maintain equipment used in various industries. It lists all essential tools and machinery, along with their inspection schedules, condition, and operational status. By ensuring that equipment is safe and functional, the checklist reduces the likelihood of breakdowns or accidents. This proactive approach enhances productivity and ensures compliance with safety regulations. It is an indispensable resource for effective equipment management. You can also see more on Field Inspection Checklist.

Purpose of an Equipment Checklist

1. Ensuring Equipment Readiness

An Equipment Checklist ensures that all machinery and tools are in proper working condition before they are used. This reduces delays caused by faulty or missing equipment and guarantees smooth operations. Regular checks also prevent unexpected downtime. By verifying readiness, the checklist helps maintain efficiency and productivity in any task.

2. Improving Workplace Safety

The checklist highlights potential safety hazards, such as worn-out parts, electrical issues, or other defects in equipment. Identifying these risks early helps to prevent accidents and injuries. Maintaining safe equipment also ensures compliance with safety regulations. This creates a secure environment for employees and boosts their confidence in workplace safety. You can also see more on Equipment Maintenance Checklist.

3. Prolonging Equipment Lifespan

Routine inspections documented in the checklist help identify wear and tear early, enabling timely maintenance and repairs. This proactive approach extends the lifespan of tools and machinery. Proper care minimizes expensive replacements and ensures the long-term reliability of equipment. It’s a cost-effective way to optimize asset management.

4. Enhancing Operational Efficiency

By systematically organizing equipment checks, the checklist ensures that all necessary tools are available and functional when needed. This minimizes interruptions caused by equipment failure or unavailability. Efficient operations lead to higher productivity and reduced project delays, ultimately benefiting the organization’s bottom line. You can also see more

5. Facilitating Compliance and Audits

The checklist serves as proof of regular inspections and maintenance, meeting compliance requirements for workplace safety standards. During audits or inspections, it demonstrates the organization’s commitment to safety and operational integrity. Keeping accurate records through the checklist ensures that regulatory obligations are consistently met. You can also see more on Daily Checklist.

How to Create an Equipment Checklist

1. Identify the Equipment to Include

Start by listing all the tools, machinery, and devices that need to be inspected or maintained. Group them by category, such as electrical tools, heavy machinery, or safety equipment, for better organization. This ensures no essential equipment is overlooked. Prioritize high-risk or frequently used items to maintain operational safety and efficiency.

2. Define Inspection Criteria

Establish specific criteria for each piece of equipment. This might include visual inspections, operational tests, or maintenance checks like oil levels, battery life, or wear on moving parts. Ensure the criteria are clear and actionable. Tailor the checklist based on equipment type, usage, and industry standards to maintain accuracy and relevance. You can also see more on Safety Checklists.

3. Create a Structured Format

Design a checklist layout that is easy to follow, whether on paper or digital platforms. Include sections for equipment name, inspection date, condition, issues identified, and actions taken. Add checkboxes, comments, or rating scales to make the checklist user-friendly. A clear format ensures consistency and usability across the team.

4. Schedule Regular Updates

Determine how often the checklist should be used—daily, weekly, monthly, or before specific operations. Align the schedule with the frequency of equipment use and manufacturer recommendations. Regular updates ensure that the checklist remains current and effective for tracking maintenance and inspection tasks.

5. Train Staff on Proper Usage

Educate employees on how to use the checklist effectively, ensuring they understand its importance and how to document findings. Provide examples and guidelines for accurate completion. This step ensures consistency and reliability in reporting, fostering a culture of accountability and safety. You can also see more on Equipment Inspection Checklist.

An Equipment Checklist is a document for ensuring safety, efficiency, and longevity of workplace tools and machinery. By systematically documenting inspections and maintenance, organizations can prevent unexpected breakdowns, promote a safe environment, and optimize operational workflows. Incorporating this proactive approach into daily routines builds confidence among employees and enhances overall productivity, leaving a lasting positive impact on workplace management.

FAQs

What is the definition of a checklist format?

A checklist is a document used to keep track of objects or actions required in the workplace. It is utilized in the workplace scheduling process to ensure that the workplace runs smoothly.

What is the definition of a basic checklist?

A simple checklist template is any method or list of activities organized in the form of a checklist; in other words, it’s a to-do list where task order is usually significant. You can also see more on Facility Inspection Checklist.

What purpose does a checklist serve?

Checklists supply detail for each step of a process, allowing you to stay organized. It can be used as a visual reminder, a method of prioritizing daily tasks, and a means to schedule all that has to be done to avoid missing deadlines. It’s simple to use, and it’s highly effective at making sure you finish all of the stages.

What industries benefit the most from Equipment Checklists?

Industries such as construction, manufacturing, healthcare, and logistics rely heavily on equipment checklists. These documents help them maintain operational efficiency and ensure compliance with safety regulations. You can also see more on Inventory Checklists.

What role does an Equipment Checklist play in audits?

During audits, an Equipment Checklist serves as documented proof of regular inspections and maintenance. It shows compliance with safety standards and demonstrates the organization’s commitment to ensuring equipment reliability.

How can digital Equipment Checklists improve efficiency?

Digital checklists streamline the inspection process by allowing real-time updates, automatic reminders, and easy data storage. They reduce paperwork and make it easier to track maintenance history, ensuring better decision-making and quicker responses to equipment issues.

What happens if equipment fails despite using a checklist?

In such cases, the checklist helps identify why the failure occurred. Was it due to overlooked issues, insufficient criteria, or human error? This sample analysis enables organizations to refine their checklists and prevent future incidents. You can also see more on Business Checklists.