Maintenance Checklist Samples

-

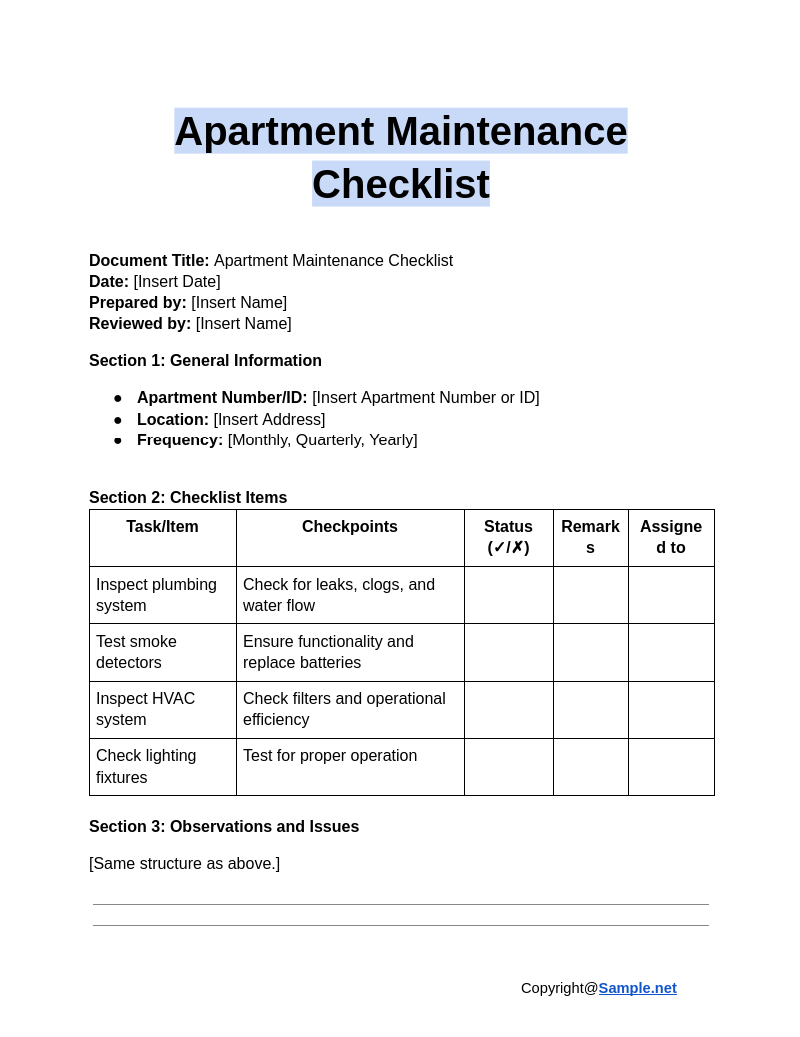

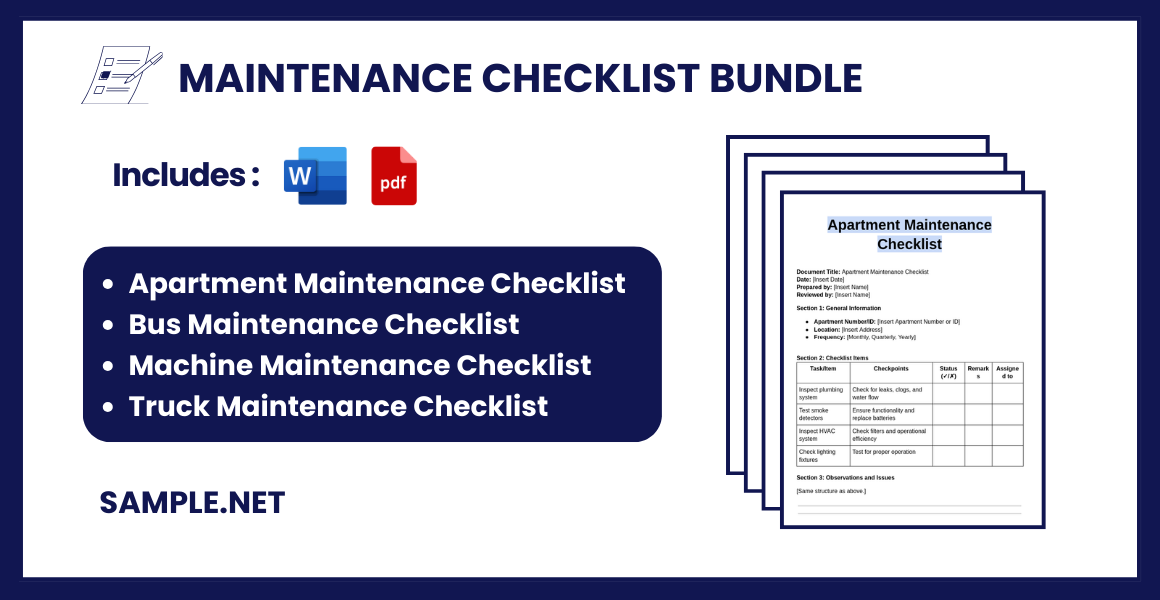

Apartment Maintenance Checklist

download now -

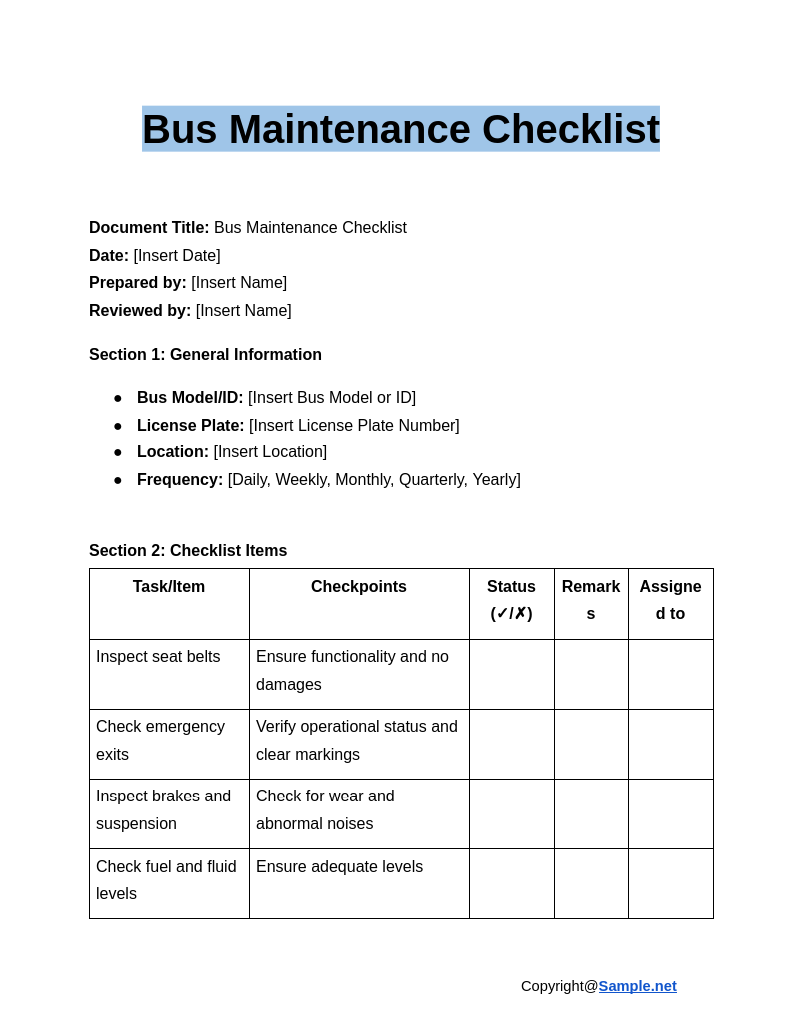

Bus Maintenance Checklist

download now -

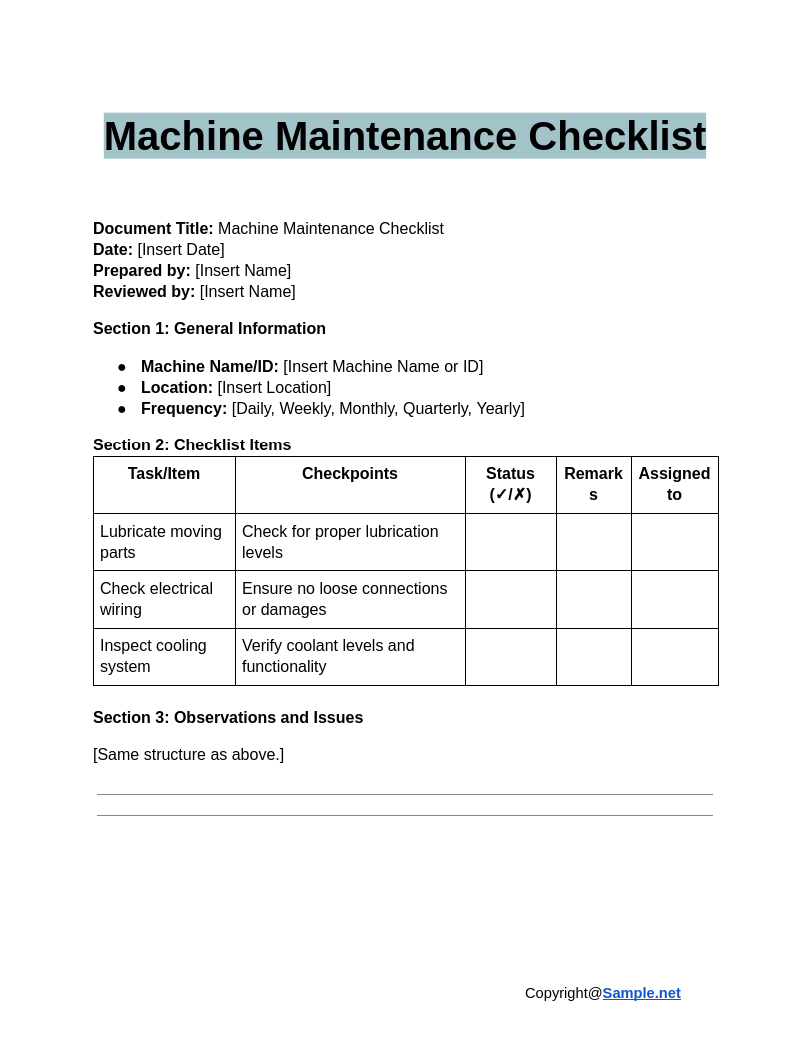

Machine Maintenance Checklist

download now -

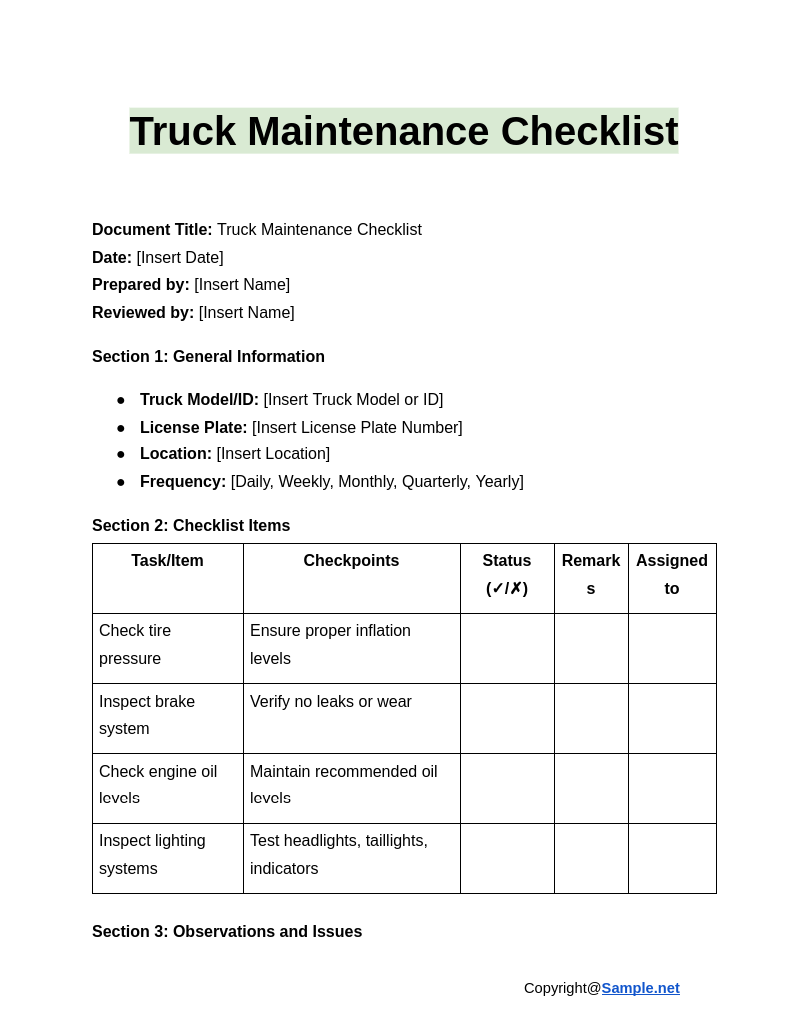

Truck Maintenance Checklist

download now -

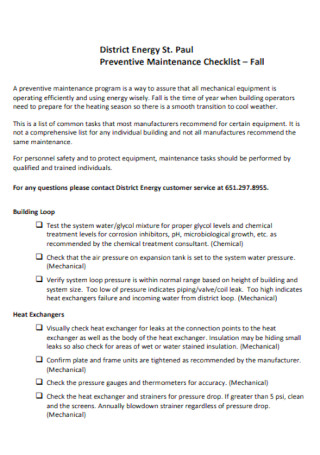

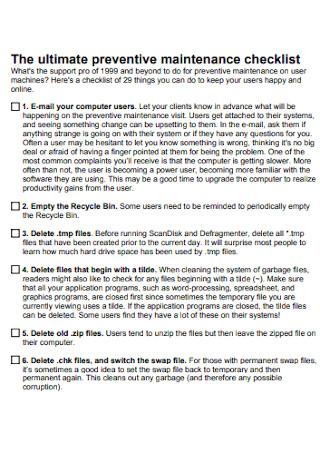

Preventative Maintenance Checklist

download now -

Bioretention Maintenance Checklist

download now -

System Operation Maintenance Checklist

download now -

Preventive Maintenance Checklist

download now -

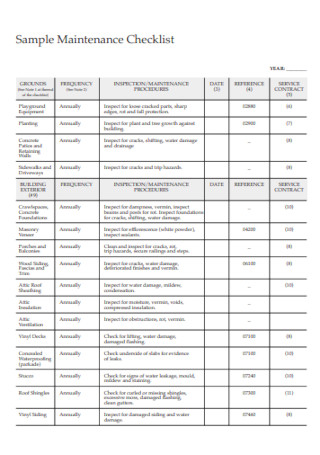

Sample Maintenance Checklist Template

download now -

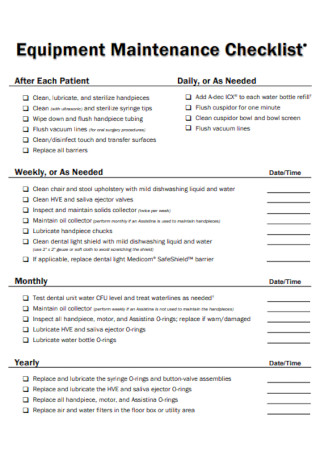

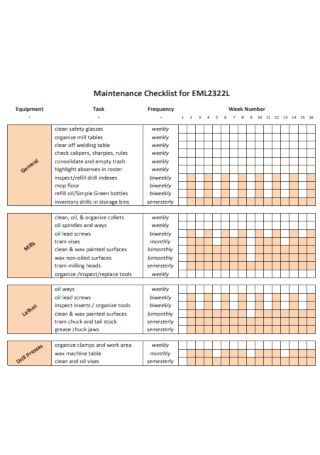

Equipment Maintenance Checklist

download now -

Sample Maintenance Checklist Example

download now -

Playground Maintenance Checklist

download now -

Equipment Maintenance Checklist Example

download now -

Formal Maintenance Checklist Template

download now -

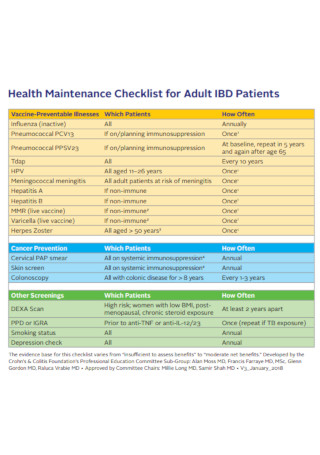

Health Maintenance Checklist for Adult

download now -

Home Maintenance Checklist

download now -

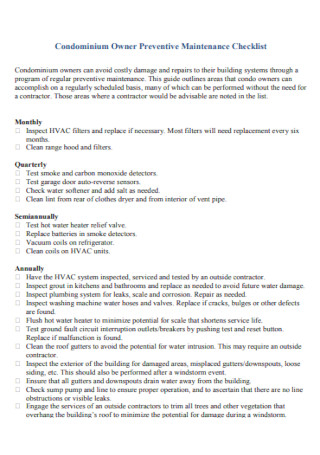

Condominium Owner Maintenance Checklist

download now -

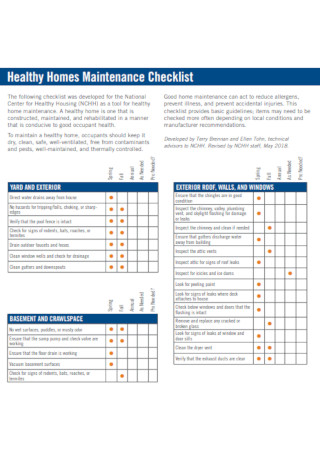

Healthy Homes Maintenance Checklist

download now -

Baghouse Maintenance Checklist

download now -

Tank Maintenance Checklist

download now -

Basic Maintenance Checklist Example

download now -

Medication Administration Checklist

download now -

Preventive Maintenance Checklist Template

download now -

Wheelchairs Maintenance Checklist

download now -

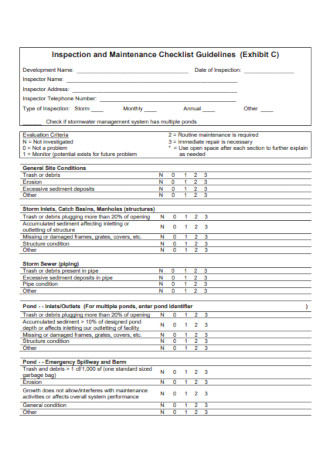

Inspection and Maintenance Checklist

download now -

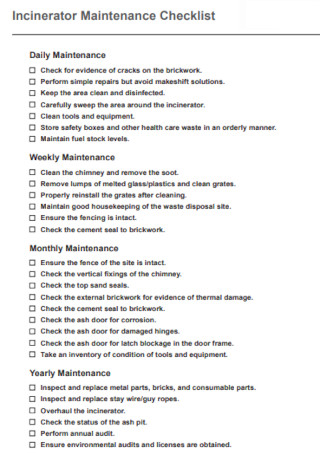

Incinerator Maintenance Checklist

download now -

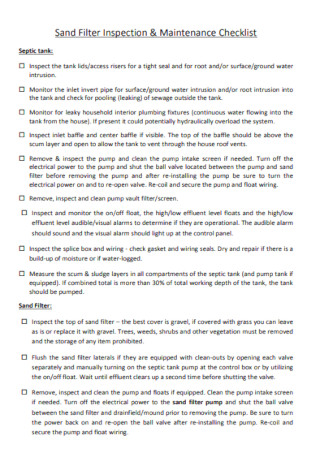

Sand Filter Inspection Maintenance Checklist

download now -

Wheelchair Maintenance Checklist

download now -

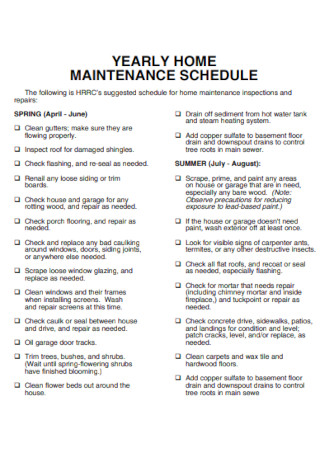

Yearly Home Maintenance Checklist

download now -

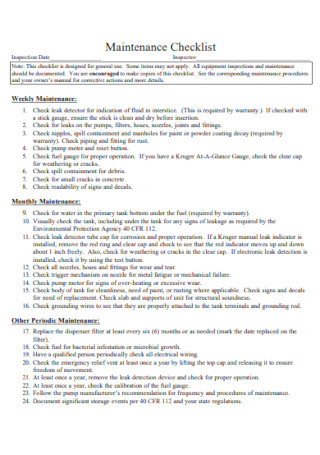

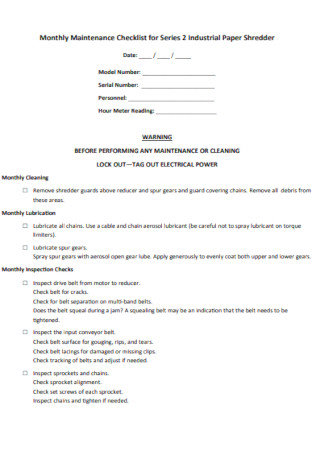

Monthly Maintenance Checklist

download now -

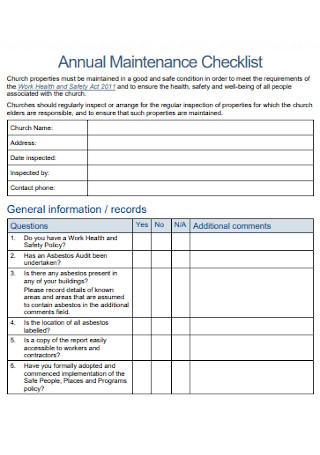

Annual Maintenance Checklist

download now -

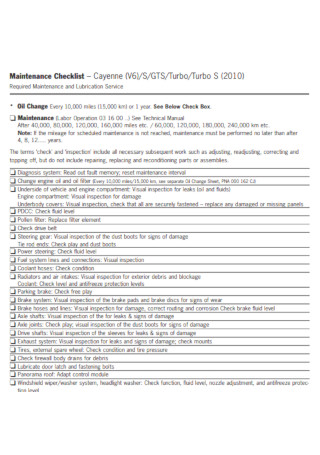

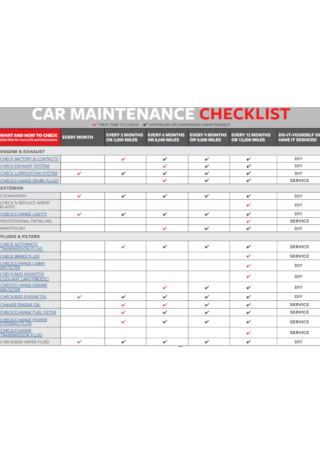

Car Maintenance Checklist Template

download now -

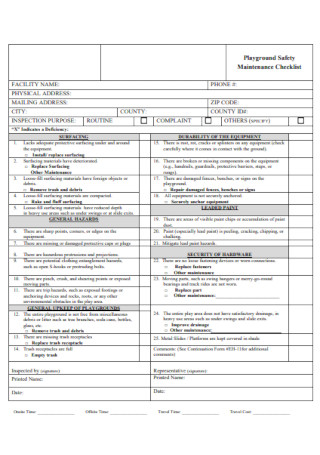

Playground Safety Maintenance Checklist

download now -

Point Furnace Maintenance Checklist

download now -

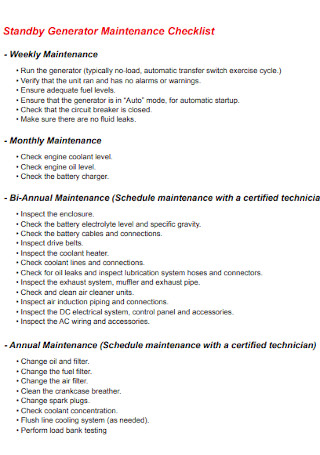

Generator Maintenance Checklist

download now -

Generator Maintenance Checklist

download now -

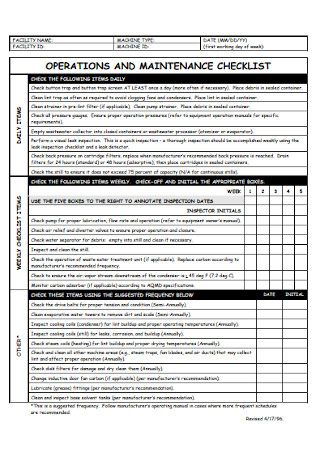

Operations and Maintenance Checklist

download now -

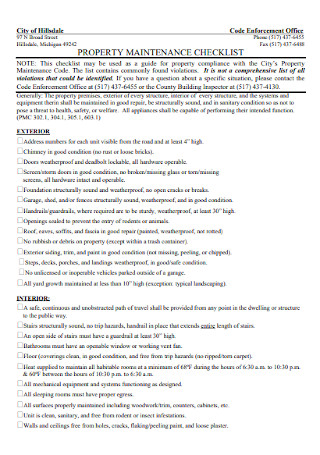

Property Maintenance Checklist

download now -

Routine Vehicle Maintenance Checklist

download now -

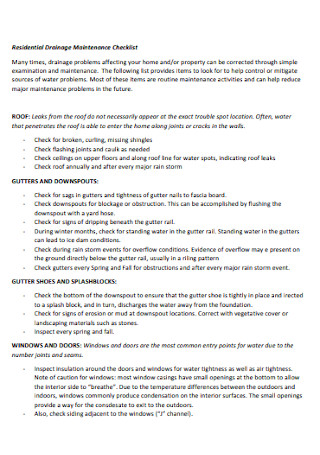

Residential Drainage Maintenance Checklist

download now -

Tractor Trailer Maintenance Checklist

download now -

Motorcycle Maintenance Service Checklist

download now -

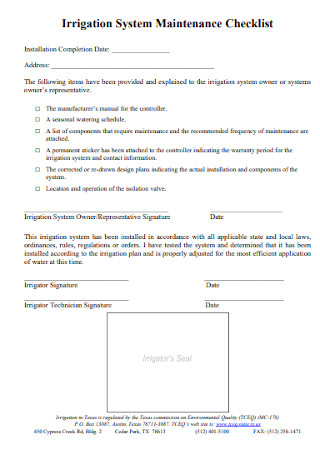

Irrigation System Maintenance Checklist

download now -

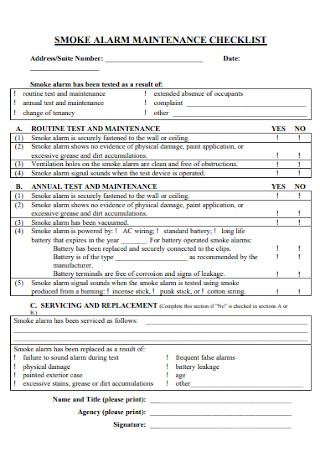

Smoke Alaram Maintenance Checklist

download now -

Rental Property Maintenance Checklist

download now -

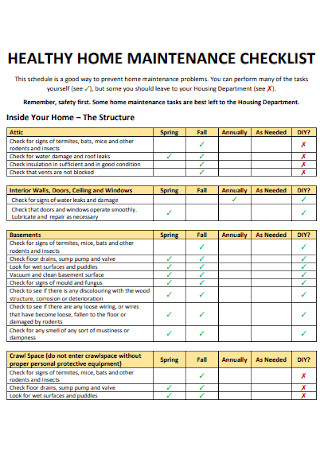

Healthy Home Maintenance Checklist

download now -

Quarterly Extruder Performance Checklist

download now -

Annual Maintenance Checklist

download now -

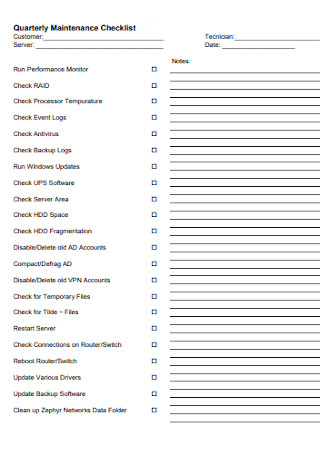

Quarterly Maintenance Checklist

download now -

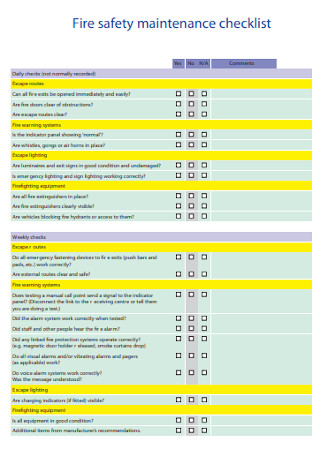

Fire Safety Maintenance Checklist

download now -

Rain Harvesting Maintenance Checklist

download now -

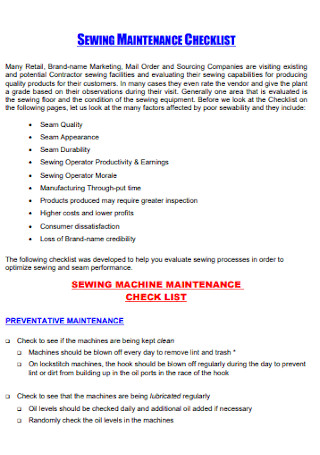

Sewing Maintenance Checklist Template

download now -

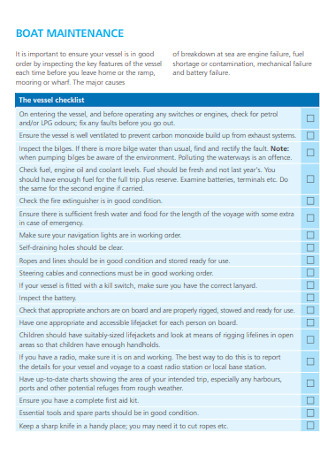

Boat Maintenance Checklist Template

download now -

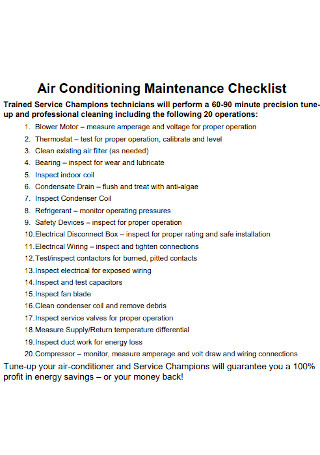

Air Conditioning Maintenance Checklist

download now -

Adult Health Maintenance Checklist

download now -

Implant Maintenance Checklist Template

download now

FREE Maintenance Checklist s to Download

Maintenance Checklist Format

Maintenance Checklist Samples

What are Maintenance Checklists?

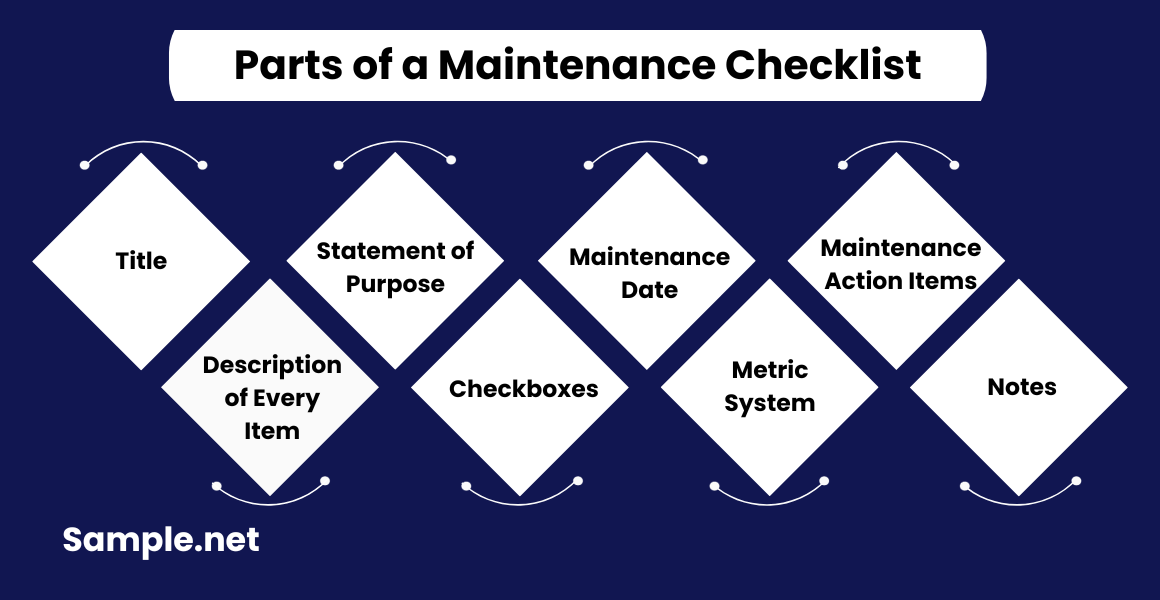

Parts of a Maintenance Checklist

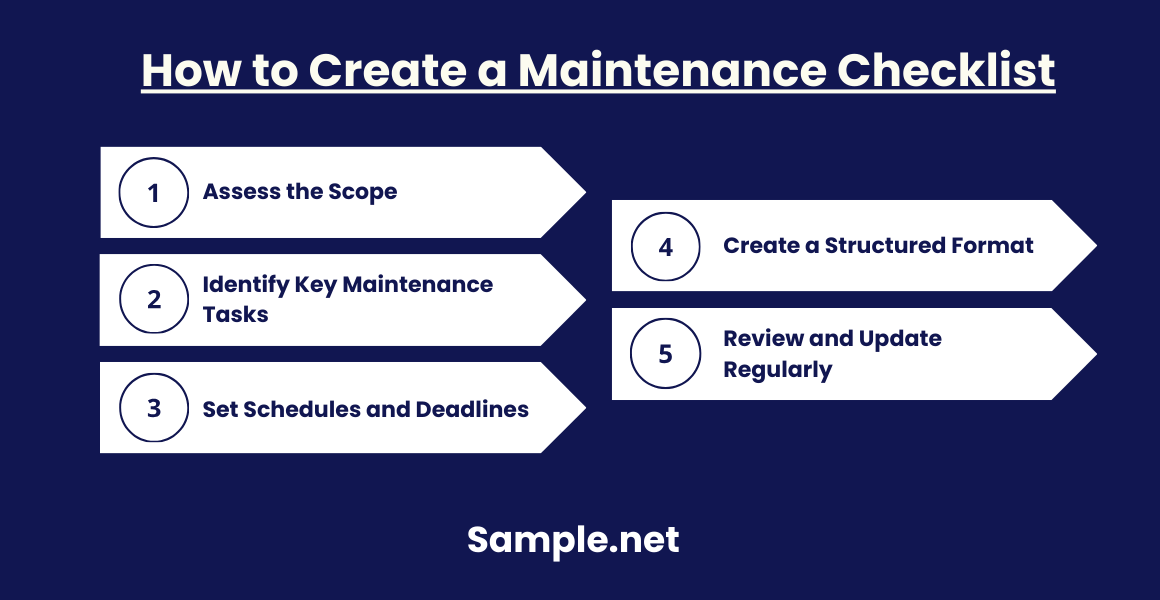

How to Create a Maintenance Checklist

FAQs

How much money should you budget for maintenance?

How can you arrange the maintenance checklist?

What are the two main formats of a maintenance checklist?

How does a maintenance checklist enhance operational efficiency?

What are the challenges in creating a maintenance checklist?

What industries benefit most from maintenance checklists?

Download Maintenance Checklist Bundle

Maintenance Checklist Format

Document Title: [Specify Equipment/System Name]

Date: [Insert Date]

Prepared by: [Insert Name]

Reviewed by: [Insert Name]

Section 1: General Information

- Equipment Name/ID: [Insert Equipment Name or ID]

- Location: [Insert Location of Equipment]

- Frequency: [Daily, Weekly, Monthly, Quarterly, Yearly]

- Inspection Start Time: [Insert Time]

- Inspection End Time: [Insert Time]

Section 2: Checklist Items

| Task/Item | Checkpoints | Status (✓/✗) | Remarks | Assigned to |

|---|---|---|---|---|

| Example: Inspect Filters | Ensure no clogging or debris buildup | |||

Section 3: Observations and Issues

- Issues Identified:

[List any issues or concerns noted during the inspection.] - Actions Taken:

[Specify actions taken to address issues during maintenance.]

Section 4: Next Steps

- Follow-Up Required: [Yes/No]

- Details of Follow-Up:

[Include a description of necessary repairs, replacement, or next inspection steps.] - Assigned Personnel: [Insert Name(s)]

- Target Completion Date: [Insert Date]

Section 5: Signatures

| Name | Role | Signature | Date |

|---|---|---|---|

| Example: John Doe | Maintenance Lead | ||

Notes:

- Use this checklist as a standard template for routine maintenance.

- Modify the checklist items to suit specific equipment or systems.

- Ensure proper documentation for audits or future reference.

What are Maintenance Checklists?

A maintenance checklist is like a strategy map of how a maintenance program should play out. It is a document that contains the itemized list of maintenance tasks that are prepared by experts or whoever is in charge of maintenance. And whoever is expected to carry out every maintenance task should follow the checklist’s instructions rigidly. Just like any checklist, whoever uses it will put a checkmark after every action item that is already finished until all maintenance tasks are done.

Parts of a Maintenance Checklist

Maintenance checklists may differ in purpose so it only makes sense that their content would be different from one example to another. However, there are standard parts that are naturally seen in most maintenance checklists. And these are the following:

How to Create a Maintenance Checklist

Creating a maintenance checklist involves several essential steps to ensure it serves its purpose effectively. Follow these steps to design a robust maintenance checklist:

Step 1: Assess the Scope

Start by determining the equipment, system, or facility that requires maintenance. Consider its operational requirements, frequency of use, and critical components that need attention. Analyze past maintenance records, if available, to understand common issues and prioritize tasks accordingly. You can also see more on Equipment Maintenance Checklist.

Step 2: Identify Key Maintenance Tasks

List all necessary tasks based on the identified scope. These may include inspections, cleaning, lubrication, part replacements, or safety checks. Refer to user manuals, manufacturer guidelines, and industry standards to ensure the tasks are relevant and comprehensive.

Step 3: Set Schedules and Deadlines

Define the frequency of each task (daily, weekly, monthly, or annually) and assign deadlines. Consider the usage patterns of the equipment or system and prioritize tasks based on their importance and potential impact.

Step 4: Create a Structured Format

Design a clear and user-friendly format for the checklist. Include sections for task descriptions, frequency, responsible personnel, and completion status. Ensure it’s easy to update and adaptable to digital formats for better accessibility and tracking. You can also see more on Machine Maintenance Checklist.

Step 5: Review and Update Regularly

Periodically review the checklist to ensure it remains relevant and effective. Add new tasks as needed, especially when new equipment is introduced or operational needs change. Remove tasks that are no longer necessary.

FAQs

How much money should you budget for maintenance?

The amount of money you allocate for the maintenance budget depends on the value of the asset itself. A common practice in home maintenance is to set aside around 1%–4% of the house’s value for the home maintenance budget.

How can you arrange the maintenance checklist?

You can organize or arrange the action items in the maintenance checklist according to their similar elements. Examples include arranging by asset, system, year, interval, season, contractor, skill level, priority level, and urgency level. You can also see more on Vehicle Maintenance Checklist.

What are the two main formats of a maintenance checklist?

Maintenance checklists have two primary formats: (1) condition-based maintenance and (2) time-based maintenance.

How does a maintenance checklist enhance operational efficiency?

By providing a structured approach, it ensures all maintenance tasks are completed systematically, reducing redundant efforts and downtime. This boosts productivity and allows teams to focus on critical operations, making the organization more efficient.

What are the challenges in creating a maintenance checklist?

Common challenges include identifying all necessary tasks, balancing detailed and practical approaches, ensuring team compliance, and regularly updating the checklist to match operational changes. You can also see more on Facility Maintenance Checklist.

What industries benefit most from maintenance checklists?

Industries like manufacturing, healthcare, automotive, and facilities management rely heavily on maintenance checklists. These tools ensure equipment reliability, compliance with regulations, and uninterrupted operations in critical sectors.