8+ Sample Preventative Maintenance Schedule

-

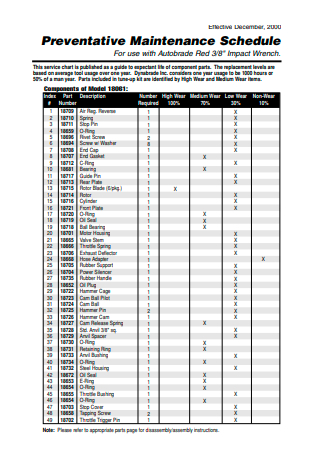

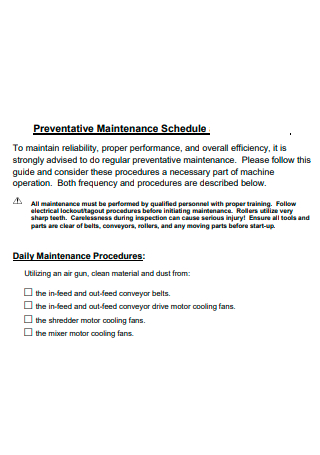

Preventative Maintenance Schedule Template

download now -

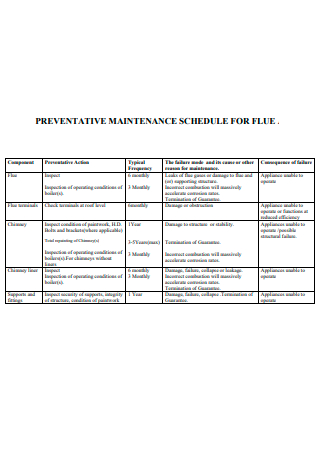

Basic Preventative Maintenance Schedule

download now -

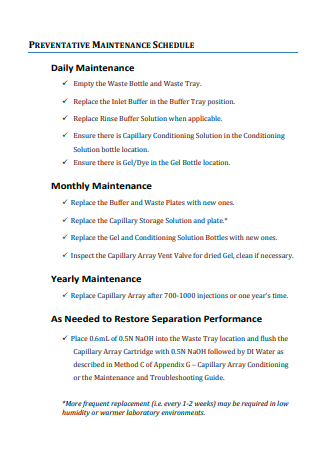

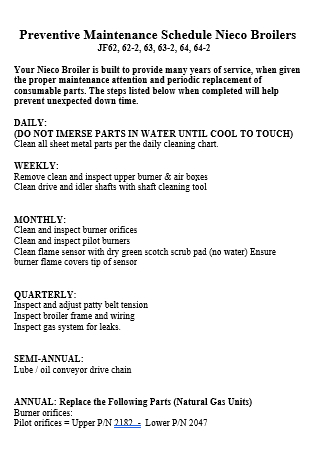

Preventative Maintenance Schedule Example

download now -

Printable Preventative Maintenance Schedule

download now -

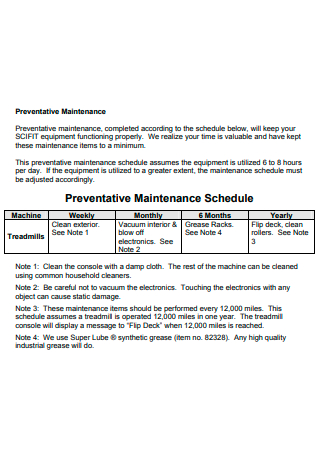

Sample Preventative Maintenance Schedule

download now -

Preventative Maintenance Schedule in PDF

download now -

Formal Preventative Maintenance Schedule

download now -

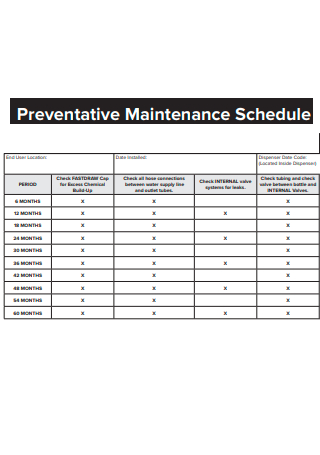

Standard Preventative Maintenance Schedule

download now -

Preventative Maintenance Schedule in DOC

download now

FREE Preventative Maintenance Schedule s to Download

8+ Sample Preventative Maintenance Schedule

What is a Preventative Maintenance Schedule?

What are the Elements of Preventative Maintenance?

Primary Types of Preventative Maintenance

Common Mistakes in Preventative Maintenance

Step by Step Process in Creating an Effective Preventative Maintenance Schedule

FAQs

What assets are suitable for preventative maintenance?

How does a preventative maintenance schedule lessen downtime?

What is a preventative maintenance software?

What is a Preventative Maintenance Schedule?

A preventative maintenance schedule refers to a set of planned maintenance tasks that take place regularly on critical components in order to avoid critical equipment failure. To define preventive maintenance, it refers to the process of caring for and servicing organizational assets to keep them in good working order through systematic inspections and observations in order to find and rectify flaws before they become a total failure. Preventative maintenance necessitates careful planning and scheduling of equipment inspection and maintenance before a problem arises. It also requires preserving correct records of previous inspections and servicing reports.

What are the Elements of Preventative Maintenance?

Preventative Maintenance comes with key elements. It is necessary to follow these elements if you want to have a successful preventative maintenance program. Here are these elements:

Primary Types of Preventative Maintenance

The tasks in a preventative maintenance are primarily completed for the purpose of preventing an equipment or a vehicle breakdown. The types of preventative maintenance can be divided into categories. Here are those:

Common Mistakes in Preventative Maintenance

Here are some of the mistakes that can be found whenever maintenance team conducts any type of preventative maintenance:

- Unclear instructions – Preventative maintenance programs can prove to be complicated and many companies make typical mistakes that can cost them valuable time and money. One of the most typical mistakes that can happen is giving instructions that are just too confusing and vague. Maintenance technicians may record a task as “done” without actually doing it due to unclear instructions. To combat this mistake, ensure that you include exact measurements and tasks to complete in the directions.

- No feasible timeframes – Although having a short window of opportunity to undertake preventative maintenance work is a good concept, it is also important to remember that by doing so too early or too late could lead to problems. A company can be wasting valuable labor and financial resources if a piece of equipment is over-maintained. In many circumstances, performing maintenance tasks too frequently has no effect on equipment failure and can just lead to a huge waste of time and resources.

- Prioritization errors – Prior to initiating a preventative maintenance program, you should need to prioritize the assets and activities that have the likelihood of preventing the failure before initiating a preventative maintenance program. You can get the most out of your preventative maintenance program if you can tie it to the pieces of equipment that are critical to keeping the production lines of your company going or maintaining the safety of your personnel.

- Mishaps in Maintenance, Repair, and Operations (MRO) parts – It is essential to maintain a well-stocked MRO inventory so that your maintenance workers have all the tools, testing equipment, and any other resources that they need to complete their tasks promptly and efficiently. Starting a maintenance task only to realize that you’re missing critical tools is not only inconvenient but can also prove to be inefficient.

- Forgetting to document work – Keeping track of your preventative maintenance program is critical for making improvements and for identifying problems. A tool that can assist you in doing this is a Computerized Maintenance Management System (CMMS). A CMMS can help you in accomplishing this goal by offering extensive analysis and data that can assist your management team in making better business decisions.

- Potential for over-maintenance – Even on some mission-critical equipment, there is still a tendency that you will over-maintain it. Some of the failures are not as hazardous to your operations compared to others, and if you’re devoting your resources to preventing every type of problem, you can end up actually wasting resources on the preventative maintenance task being performed. To combat this, it is essential to know how to achieve a balance between failure prevention and reactive repair work.

Step by Step Process in Creating an Effective Preventative Maintenance Schedule

Setting up an effective preventative maintenance schedule will prove to be a great long-term investment you can make in the company. The maintenance team will save a great amount of money and will also have to deal with fewer maintenance-related crises in the future. With that being said, here are some steps to follow to create an effective schedule:

1. Prioritize assets in order of maintenance needs.

It is recommended in this step that you make a list of your company’s most critical equipment and start the Preventative Maintenance Schedule with them. This enables you and your team to start slowly as you begin your transition to a proactive workflow and mindset. You will give your company the biggest long-term profits by selecting equipment that will require a lot of resources (time and money) should they unexpectedly fail. By investing in preventative maintenance, the expenses of reactive maintenance can be avoided, which tend to be much higher. Your return will also be higher if you choose equipment that is newer first.

2. Collect data about the asset.

After you’ve decided which equipment to include in your preventative maintenance plan, it is now time to gather information on any service orders and unplanned downtime that each asset has had over the last several years. Afterwards, start verifying what types of problems each asset has presented and how often they occurred. It gives you perspective on how much you should be spending on preventative maintenance work.

3. Make projections about maintenance needs.

Every asset is unique in terms of its operational lifetime and maintenance requirements; as a result, you should gather information about each piece of equipment prior to creating their respective maintenance checklist. The asset’s Original Equipment Manufacturer (OEM) recommendations are generally the main source of information. This is a manufacturer-supplied manual that typically includes the maintenance schedules, crucial spare part usage instructions, and basic maintenance work instructions. Another great source of information would be your maintenance team. By talking to them, you might find out that you have to schedule regular maintenance to one of your assets because no spare parts were available prior to that asset’s breakdown.

4. Put together the initial preventative maintenance plan.

In this step, you should start to write down all the necessary preventative maintenance tasks for every asset. Also, include how often you should need to perform these tasks. It is also usually not a bad idea to include more additional notes for certain tasks to be completed so that the technician who will perform the maintenance will know exactly what to do. Once the initial preventative maintenance plan is ready, you can start putting it into practice.

5. Verify the progress and adjust.

As the maintenance team gets acclimatized with the workflow that is created, you should also be monitoring the progress and making the necessary adjustments. You can expect to perform any regular adjustments as the results start to materialize. By doing this, it ensures that you get an optimum return on the investment that you are making. It is also important to keep in mind that the initial preventative maintenance schedule will never be perfect. Just make sure that you are always prepared to make the necessary adjustments to your maintenance plan based on the insights and feedback that you get from your maintenance technicians.

FAQs

What assets are suitable for preventative maintenance?

The assets that are suitable for preventative maintenance include those that have failure modes that can be prevented with regular maintenance, assets that have a likelihood of failure that increases with time or use, and those assets that are critical to production, business operations, health, or safety.

How does a preventative maintenance schedule lessen downtime?

With an effective preventative maintenance schedule in place, maintenance managers are presented with an opportunity to decrease operation interruptions and increase productivity. The schedule is usually contained in and automated with a CMMS that comes with preventative maintenance software. However, as stated earlier in the article, the maintenance managers should also be aware of over-maintaining their assets as this can lead to a waste of precious resources.

What is a preventative maintenance software?

A preventative maintenance software allows you to schedule maintenance, send warnings to appropriate individuals when a maintenance task is due and boost resource availability and allocation, all of which helps you complete planned activities much faster and more effectively. As a result, you’ll be able to streamline operations that will greatly aid you in the success of performing preventative maintenance. Preventative maintenance software can range from extremely specialized maintenance systems to giant platforms that connect maintenance tasks to other types of business units.

An example of such software is the Computerized Maintenance Management System (CMMS), which allows facilities to plan, track, and optimize work orders, inventory, and everything else associated with maintenance. This software also helps maintenance teams keep detailed and centralized records of all types of assets, equipment, and completed work.

Preventative maintenance is scheduled according to time or usage-based triggers. Its main purpose is to lessen the likelihood of equipment or vehicle breakdowns. When it is implemented properly, it can result in huge savings over time because the assets can last longer, can use less energy than what is required, and can result in fewer interruptions to the production processes. It can also help promote safety within the workplace. Also, having an effective preventative maintenance schedule in place can be a huge step in the right direction of preventative maintenance planning. In this article, examples of an effective preventative maintenance schedule are posted so that you can have something to look at as a reference should you need to make one for the place you work at.